- Home

- Blog

- Leading Component Manufacturer in China Expands Production Capacity and R&D for Improved Products

Leading Component Manufacturer in China Expands Production Capacity and R&D for Improved Products

By:Admin

As the demand for electronic components continues to rise, China Component Manufacturer has recently announced that it is expanding its production capacity to meet the increasing market need. The company, which has been a leading provider of high-quality electronic components for over a decade, is making significant investments in its manufacturing facilities to ensure that it can continue to meet the needs of its customers in the rapidly evolving electronics industry.

With a focus on innovation and technological advancement, China Component Manufacturer has established itself as a key player in the global market for electronic components. The company's extensive product range includes resistors, capacitors, inductors, and various other electronic components that are essential for the production of a wide variety of electronic devices, from consumer electronics to industrial equipment.

One of the key factors contributing to the company's success is its commitment to quality and reliability. China Component Manufacturer has implemented strict quality control measures at every stage of the manufacturing process to ensure that its products meet the highest standards. This dedication to quality has earned the company a solid reputation among its customers, who rely on its components to power their electronic devices.

In response to the increasing demand for its products, China Component Manufacturer is now ramping up its production capacity to ensure that it can continue to meet the needs of its customers. The company's manufacturing facilities are being expanded and modernized to increase efficiency and productivity, allowing it to produce a larger volume of components without compromising on quality.

In addition to expanding its manufacturing capabilities, China Component Manufacturer is also investing in research and development to stay ahead of the curve in the fast-paced electronics industry. The company's team of engineers and technologists are constantly working on developing new and improved components that are in line with the latest technological trends and advancements. By staying at the forefront of innovation, China Component Manufacturer is positioning itself as a leader in the electronic components market.

The expansion of China Component Manufacturer's production capacity comes at a time when the global demand for electronic components is on the rise. With the increasing adoption of advanced technologies such as 5G, IoT, and artificial intelligence, the demand for high-quality electronic components is expected to grow substantially in the coming years. This presents a significant opportunity for China Component Manufacturer to solidify its position as a leading provider of electronic components on the global stage.

The company's commitment to meeting the evolving needs of the electronics industry is reflected in its efforts to expand its production capacity. By investing in its manufacturing facilities and staying ahead of technological advancements, China Component Manufacturer is well-positioned to continue serving its customers with reliable, high-quality electronic components for a wide range of applications.

In conclusion, China Component Manufacturer's expansion of its production capacity is a testament to the company's commitment to meeting the growing demand for electronic components. With its dedication to quality, innovation, and reliability, the company is well-positioned to continue serving as a key player in the global market for electronic components. As the electronics industry continues to evolve, China Component Manufacturer is poised to lead the way with its expanded production capabilities and forward-looking approach to technological advancement.

Company News & Blog

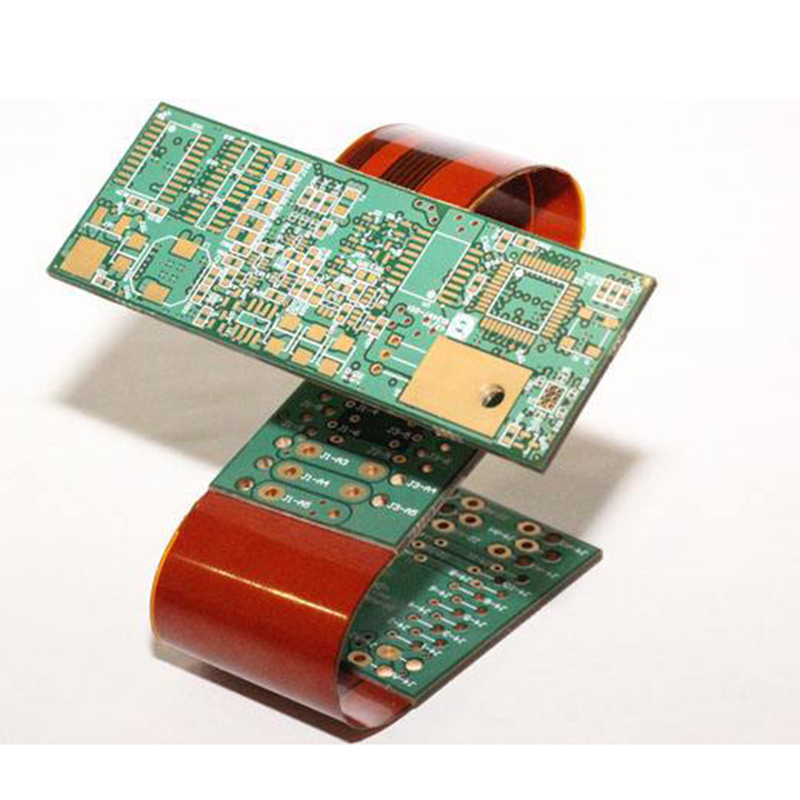

Understanding the Flex PCB Manufacturing Capabilities in China

China Flex PCB Capabilities Expands to Meet Growing DemandChina has long been known as a global leader in electronics manufacturing, and the country's Flex PCB capabilities are no exception. With a growing demand for flexible printed circuit boards (Flex PCBs) in various industries, Chinese manufacturers have been investing in expanding their capabilities to meet this demand.One such company that has been at the forefront of this expansion is {}. {} has been a leading manufacturer of Flex PCBs for many years and has recently made significant investments to further enhance their capabilities in this area. With state-of-the-art production facilities and a team of experienced engineers and technicians, {} is well positioned to cater to the increasing demand for Flex PCBs in the market.Flex PCBs are widely used in applications where space is limited, and flexibility is required. They are commonly used in consumer electronics, automotive, healthcare, and industrial applications. With the development of new technologies and the increasing trend towards miniaturization, the demand for Flex PCBs has been on the rise. This has prompted many manufacturers, including those in China, to invest in expanding their capabilities to meet this growing demand.One of the key advantages of Flex PCBs is their ability to bend and flex without breaking, making them ideal for use in compact and unconventional designs. This flexibility allows for greater freedom in the design of electronic devices and can lead to innovative and creative product designs. With the advancement of technology, Flex PCBs are also becoming more sophisticated, with the ability to support high-speed data transmission and complex circuitry.China's strength in electronics manufacturing and its growing expertise in Flex PCB production have made it a preferred destination for companies looking to source high-quality Flex PCBs. With its well-established supply chain and manufacturing infrastructure, China has the capabilities to produce Flex PCBs in large volumes and at competitive prices. This has made it an attractive option for businesses looking to outsource their Flex PCB manufacturing needs.Additionally, China's commitment to investing in research and development has led to advancements in Flex PCB technology, further enhancing the country's capabilities in this area. This, combined with the experience and expertise of Chinese manufacturers, has solidified China's position as a global leader in Flex PCB production.With the expansion of capabilities in China, companies like {} are well positioned to cater to the increasing demand for Flex PCBs from both domestic and international clients. {}'s strong focus on quality and innovation has enabled it to build a solid reputation in the industry, and the company is well poised to capitalize on the growing opportunities in the Flex PCB market.In conclusion, the expansion of Flex PCB capabilities in China is a positive development for the electronics industry. With the country's expertise in electronics manufacturing and its commitment to innovation, China is well positioned to meet the growing demand for Flex PCBs. Companies like {} are at the forefront of this expansion, and their investments in advanced technologies and production capabilities will only serve to further strengthen China's position as a global leader in Flex PCB production.

High-Quality SMD PCB Assembly Manufacturer Services for Your Electronic Devices

As a leading SMD PCB assembly manufacturer, {} has established itself as a reliable and reputable provider of high-quality electronic manufacturing services. With a commitment to delivering cutting-edge solutions and innovative technology, the company has solidified its position in the industry as a trusted partner for businesses seeking top-notch PCB assembly services.{} is dedicated to meeting the unique needs and specifications of each client, offering comprehensive SMD (Surface Mount Device) PCB assembly capabilities that encompass a wide range of applications and industries. With state-of-the-art facilities and advanced equipment, the company is able to handle complex assembly processes with precision and efficiency, ensuring that the finished products meet the highest standards of quality and reliability.The company's expertise in SMD PCB assembly extends to a variety of electronic components, including integrated circuits, resistors, capacitors, and diodes. With a focus on advanced manufacturing techniques and stringent quality control measures, {} is able to produce PCB assemblies that are tailored to the specific requirements of each client, whether it's for consumer electronics, medical devices, telecommunications equipment, or industrial machinery.In addition to its technical proficiency, {} is also committed to providing exceptional customer service and support throughout the entire manufacturing process. From initial design and prototyping to full-scale production and testing, the company works closely with its clients to ensure that their expectations are met and exceeded. With a team of experienced engineers and technicians, {} is capable of addressing the most demanding challenges and delivering reliable, cost-effective solutions.One of the key differentiators for {} is its ability to offer turnkey solutions for SMD PCB assembly, providing a comprehensive range of services that streamline the manufacturing process and reduce time-to-market for its clients. From sourcing and procurement of electronic components to PCB layout and assembly, the company handles every aspect of the production cycle, allowing its clients to focus on their core competencies and business objectives.{}'s commitment to quality and excellence is evident in its adherence to industry standards and certifications, including ISO 9001 and IPC-A-610. These certifications demonstrate the company's dedication to upholding the highest levels of quality and reliability in its manufacturing processes, ensuring that its clients receive products that meet or exceed their expectations.With a proven track record of success and a strong reputation for customer satisfaction, {} is poised to continue its leadership in the SMD PCB assembly industry. By leveraging its technical expertise, advanced capabilities, and commitment to excellence, the company is well-positioned to meet the evolving demands of the electronics market and provide innovative solutions for its clients' SMD PCB assembly needs.As the demand for high-quality electronic manufacturing services continues to grow, {} remains focused on expanding its capabilities and enhancing its offerings to meet the needs of its diverse clientele. With a steadfast commitment to innovation and customer satisfaction, the company is poised for continued success as a leading provider of SMD PCB assembly solutions.

Professional LED PCB Assembly Factory for OEM Projects

OEM LED PCB Assembly Factory, a leading provider of cutting-edge LED PCB assembly solutions, is making waves in the electronics manufacturing industry with its state-of-the-art facilities and innovative approach to LED assembly. With a commitment to quality, efficiency, and customer satisfaction, the factory has quickly risen to prominence as a trusted partner for OEMs around the world.At the heart of OEM LED PCB Assembly Factory's success is its dedication to research and development. The company invests heavily in the latest technologies and manufacturing techniques to ensure that its LED PCB assemblies are of the highest quality. This relentless pursuit of innovation has enabled the factory to stay ahead of the curve and deliver products that exceed industry standards.One of the key differentiators for OEM LED PCB Assembly Factory is its fully automated assembly process. By leveraging advanced machinery and robotics, the factory is able to achieve unparalleled precision and consistency in its LED PCB assemblies. This not only results in superior product quality, but also allows the factory to meet tight production deadlines with ease.In addition to its cutting-edge manufacturing capabilities, OEM LED PCB Assembly Factory also prides itself on its skilled workforce. The company employs a team of experienced engineers and technicians who are experts in LED assembly. Their deep industry knowledge and attention to detail ensure that every LED PCB assembly that leaves the factory is of the highest standard.Furthermore, the factory adheres to strict quality control measures at every stage of the production process. From initial design and prototyping to final assembly and testing, OEM LED PCB Assembly Factory maintains rigorous quality checks to guarantee that its products meet and exceed customer expectations.The company's commitment to sustainability is another aspect that sets it apart in the industry. OEM LED PCB Assembly Factory utilizes eco-friendly manufacturing processes and materials to minimize its environmental impact. This aligns with the growing demand for sustainable and energy-efficient LED lighting solutions in the market.OEM LED PCB Assembly Factory's dedication to excellence has not gone unnoticed. The factory has established a strong reputation for delivering top-notch LED PCB assemblies to a wide range of industries, including automotive, aerospace, consumer electronics, and more. Its proven track record and commitment to customer satisfaction have earned the trust of leading OEMs and positioned the factory as a preferred supplier in the global market.Looking ahead, OEM LED PCB Assembly Factory is poised for continued growth and success. The company is constantly exploring new opportunities for innovation and expansion, with a focus on meeting the evolving needs of its customers. By staying at the forefront of LED assembly technology and maintaining its high standards of quality, the factory is well-positioned to lead the way in the competitive electronics manufacturing landscape.With its cutting-edge capabilities, skilled workforce, and unwavering commitment to excellence, OEM LED PCB Assembly Factory is a force to be reckoned with in the LED assembly industry. As demand for high-quality LED lighting solutions continues to rise, the factory stands ready to meet and exceed the expectations of OEMs worldwide.

High-Quality PCBA Production Manufacturing Services for Your Business

Pcba Production Manufacturer, a leading electronics manufacturing company in the industry, has been making strides in the production of high-quality printed circuit board assemblies (PCBAs). Their commitment to innovation and customer satisfaction has earned them a spot among the top PCBA manufacturers in the market.Established in (replace with date), Pcba Production Manufacturer has been dedicated to providing cutting-edge solutions for various industries, including automotive, aerospace, consumer electronics, and medical devices. With a state-of-the-art facility and a team of skilled engineers and technicians, the company has the capability to handle complex PCBA production projects with precision and efficiency.One of the key factors that set Pcba Production Manufacturer apart from its competitors is its commitment to quality. The company adheres to strict quality control measures throughout the production process, ensuring that each PCBA meets the highest standards of performance and reliability. From component sourcing to assembly and testing, every step is meticulously managed to deliver products that exceed customer expectations.In addition to quality, Pcba Production Manufacturer places a strong emphasis on innovation. The company invests heavily in research and development to stay ahead of the curve in terms of technology and manufacturing processes. This allows them to offer advanced solutions that meet the evolving needs of the industry and their customers.Furthermore, Pcba Production Manufacturer prides itself on its customer-centric approach. The company works closely with clients to understand their specific requirements and provide tailored solutions to meet their needs. Whether it's a small-scale prototype or a large-scale production run, Pcba Production Manufacturer is committed to delivering on time and within budget.As part of their commitment to sustainability, Pcba Production Manufacturer also places a strong emphasis on environmental responsibility. The company adheres to strict environmental regulations and implements eco-friendly practices in its manufacturing processes. This includes reducing waste, conserving energy, and recycling materials whenever possible.With a strong track record of delivering high-quality PCBAs and a dedication to continuous improvement, Pcba Production Manufacturer has earned the trust and loyalty of numerous clients across the globe. Their reputation for excellence has positioned them as a preferred partner for businesses looking for reliable and innovative PCBA manufacturing solutions.Looking ahead, Pcba Production Manufacturer is poised to continue its growth and expansion in the industry. The company is committed to staying at the forefront of technology and delivering exceptional value to its customers. With a focus on quality, innovation, and customer satisfaction, Pcba Production Manufacturer is set to maintain its position as a leader in the PCBA manufacturing sector.In conclusion, Pcba Production Manufacturer has proven itself as a top contender in the PCBA manufacturing industry. With a strong focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses looking for high-quality PCBAs. As the company continues to grow and expand, it remains dedicated to delivering cutting-edge solutions and exceeding customer expectations.

Top Design Suppliers for OEM Flex PCB: Enhancing Your Electronic Device's Performance

Title: Flex PCB Design Suppliers Introduce Innovative Solutions for OEMs[City, Date] - In a rapidly evolving world of advanced technologies, the demand for flexible printed circuit boards (Flex PCBs) has been steadily increasing. Catering to this demand, renowned OEM Flex PCB design suppliers have taken the lead in introducing innovative solutions that offer enhanced flexibility and functionality to various industries. With a strong commitment to design excellence and cutting-edge manufacturing techniques, these suppliers have positioned themselves at the forefront of the industry, meeting the ever-growing needs of Original Equipment Manufacturers (OEMs).Flex PCBs have revolutionized the electronics industry, providing intricate designs and flexible circuitry that traditional rigid boards cannot achieve. Their ability to bend, twist, and conform to complex shapes has opened up new possibilities in product development across sectors such as automotive, medical, aerospace, and consumer electronics. Offering high reliability, compactness, and improved assembly efficiency, Flex PCBs have become a key component in advanced electronics.Leading the charge, [Company Name] is a prominent Flex PCB design supplier, renowned for their dedication to cutting-edge technology and superior product quality. With decades of industry expertise, they have positioned themselves as a reliable partner for OEMs seeking innovative solutions.[Company Name] combines their extensive repertoire of flexible circuit design capabilities with highly advanced manufacturing processes. By investing in state-of-the-art machinery and equipment, they have ensured the highest precision and efficiency in producing Flex PCBs that cater to the diverse needs of OEMs worldwide.Their commitment to continuous innovation is reflected in their offerings, which span a wide range of specialized Flex PCB designs. From single-layer and double-layer Flex PCBs to multilayer and rigid-flex circuits, [Company Name] provides flexible solutions that can adapt to various design requirements. They understand the importance of customizable solutions for OEMs, offering tailored designs that adhere to the specific demands of each industry.With a focus on research and development, [Company Name] is at the forefront of emerging Flex PCB technologies. They have implemented advanced solutions like embedded passive technology, flex-to-install components, and 3D flexible circuits. These innovations push the boundaries of what Flex PCBs can achieve, fostering improved performance, compactness, and reliability.In addition to design expertise, [Company Name] emphasizes the importance of strict quality control measures. They adhere to rigorous inspection processes throughout the manufacturing cycle, ensuring zero defects and meeting the highest industry standards. All Flex PCBs undergo comprehensive testing and validation, guaranteeing the utmost durability and reliability.With a global clientele, [Company Name] has successfully established long-standing partnerships with renowned OEMs worldwide. Their customer-centric approach, from initial consultation to final delivery, ensures that they align their solutions with the specific needs and goals of each client.Divulging their future plans, [Company Name] aims to continue their focus on research and development, driving the industry forward with groundbreaking innovations. They are committed to exploring new areas of application for Flex PCBs, such as Internet of Things (IoT) devices, wearable technology, and advanced sensor systems.As the demand for Flex PCBs continues to surge, OEMs can rely on [Company Name] and other leading suppliers to provide cutting-edge flex circuit solutions that enable them to stay ahead in their respective industries. With their expertise in design, manufacturing, and quality control, these suppliers are revolutionizing the capabilities of flexible electronics and shaping the future of advanced technology.In conclusion, Flex PCB design suppliers, including [Company Name], are paving the way for OEMs with their innovative and customizable solutions. By combining design excellence, advanced manufacturing processes, and relentless focus on quality control, these suppliers empower OEMs to develop advanced products that cater to evolving market demands. With their commitment to continuous research and development, they are poised to drive the industry forward, revolutionizing the applications of Flex PCBs in various sectors.

Quality SMD PCB Assembly Services for Your Electronics

SMD PCB Assembly: The Next Step in Cutting-Edge TechnologyIn the fast-paced world of electronic manufacturing, staying ahead of the curve is a top priority for businesses looking to remain competitive. The introduction of surface mount device (SMD) technology has revolutionized the way printed circuit boards (PCBs) are assembled, leading to faster production times, increased efficiency, and smaller, more compact electronic devices. As a leader in electronic manufacturing services, {} has embraced this cutting-edge technology to offer its customers the latest advancements in PCB assembly.With SMD technology, electronic components are mounted directly onto the surface of the PCB, as opposed to being inserted through pre-drilled holes. This not only saves valuable space on the board, but also allows for a higher component density, leading to more complex and advanced electronic designs. Additionally, SMD assembly allows for automated production processes, reducing the need for manual labor and minimizing the potential for human error.At {}, we have fully integrated SMD assembly into our manufacturing processes, allowing us to offer our customers a range of advantages. By utilizing state-of-the-art equipment and highly trained personnel, we are able to achieve a level of precision and accuracy that was once thought to be impossible. This has resulted in faster turnaround times for our customers, as well as improved product quality and consistency.One of the key benefits of SMD assembly is its ability to accommodate smaller and lighter electronic components, which is particularly important in the development of portable and handheld devices. As consumer demand for compact, high-performance electronics continues to grow, the need for SMD technology has never been greater. By investing in cutting-edge SMD assembly capabilities, {} is positioned to meet the evolving needs of the electronics industry and provide our customers with innovative solutions for their products.Furthermore, SMD technology allows for increased design flexibility, as it enables the creation of more intricate and space-efficient circuitry. This opens up new opportunities for product developers to explore unique and creative designs, ultimately leading to more advanced and sophisticated electronic devices. With our expertise in SMD assembly, {} is proud to support our customers in bringing their most ambitious ideas to life.In addition to its many technical advantages, SMD assembly also offers cost savings for manufacturers. By streamlining production processes and minimizing the use of materials, SMD technology can result in lower manufacturing costs and improved profitability. This is particularly valuable for businesses operating in competitive markets, where efficiency and cost-effectiveness are critical factors for success.At {}, we are committed to staying at the forefront of electronic manufacturing technology, and our adoption of SMD assembly is a testament to that commitment. By embracing the latest advancements in PCB assembly, we are able to offer our customers the highest level of quality, efficiency, and innovation. With our extensive experience and dedication to excellence, {} is the ideal partner for businesses seeking to leverage the power of SMD technology in their electronic products.As we look towards the future, {} is poised to continue leading the way in electronic manufacturing, driving innovation and delivering superior solutions for our customers. With SMD assembly as a cornerstone of our manufacturing capabilities, we are excited to help our customers realize their most ambitious visions and achieve success in an ever-evolving industry.

Understanding the Latest PCBA Quality Standards: What You Need to Know

In recent news, the PCBA quality standards have been a topic of great importance in the electronic manufacturing industry. With the increasing demand for high-quality and reliable electronic products, the need for stringent quality standards for printed circuit board assembly (PCBA) has become more apparent than ever.In response to this growing need, many companies have been striving to ensure that their PCBA processes adhere to the highest quality standards. One such company that has been leading the way in this regard is {Company Name}.{Company Name} has built a reputation for excellence in the electronic manufacturing industry. With state-of-the-art facilities and a team of highly skilled professionals, the company has been at the forefront of producing top-notch PCBA products for various applications. The company's commitment to quality and innovation has earned them a loyal customer base and an esteemed position in the industry.To uphold its commitment to quality, {Company Name} has implemented stringent PCBA quality standards throughout its manufacturing processes. From the selection of high-quality components to the assembly and testing stages, every step of the PCBA process at {Company Name} is closely monitored to ensure that the final products meet the highest standards of quality and reliability.One key aspect of {Company Name}'s PCBA quality standards is the use of advanced technology and cutting-edge equipment. The company continuously invests in the latest manufacturing equipment and technologies to ensure that its PCBA processes are efficient and precise. This not only helps in maintaining the quality of the products but also allows for faster production cycles, enabling {Company Name} to meet the demands of its customers in a timely manner.Furthermore, {Company Name} places a strong emphasis on continuous improvement and innovation. The company regularly reviews and updates its quality standards to align with the latest industry practices and technological advancements. This proactive approach ensures that {Company Name} stays ahead of the curve and delivers products that are at the forefront of innovation and quality.In addition to adhering to internal quality standards, {Company Name} also complies with industry-specific regulations and certifications. The company's commitment to quality and compliance has earned it various certifications and accolades, further solidifying its position as a trusted manufacturer of high-quality PCBA products.As a result of these efforts, {Company Name} has emerged as a preferred partner for many businesses looking for reliable PCBA solutions. The company's products are widely used in various industries, including telecommunications, medical devices, consumer electronics, and automotive applications, among others.Looking ahead, {Company Name} remains committed to upholding the highest PCBA quality standards and delivering exceptional products to its customers. The company's dedication to excellence and innovation continues to set it apart in the electronic manufacturing industry, making it a force to be reckoned with in the market.In conclusion, the PCBA quality standards have become increasingly important in the electronic manufacturing industry, and {Company Name} has been a standout performer in this regard. With its unwavering commitment to quality, innovation, and compliance, the company has established itself as a leader in delivering high-quality PCBA products to meet the demands of various industries. As the industry continues to evolve, one can expect {Company Name} to remain at the forefront, setting new benchmarks for PCBA quality standards and exceeding the expectations of its customers.

Latest Advancements in PCB Technology Unveiled in Industry News

PCB Technology Revolutionizes the Electronics IndustryThe electronics industry has been revolutionized by the advent of PCB technology, which has enabled the development of smaller, more efficient, and more reliable electronic devices. PCB technology has quickly become the standard in the electronics industry, enabling the production of complex electronic circuits that are essential for advanced technology such as smartphones, computers, and medical devices.One company at the forefront of PCB technology is {}. With over 20 years of experience in the electronics industry, {} has established itself as a leader in the development and production of high-quality PCBs. The company's commitment to innovation and excellence has enabled it to provide cutting-edge solutions to its customers, and its expertise in PCB technology has played a crucial role in driving the advancement of the electronics industry.PCB technology, also known as printed circuit board technology, involves the use of conductive pathways printed or etched onto a flat board made of insulating material. These pathways allow for the connection of electronic components such as resistors, capacitors, and integrated circuits, forming a complete electronic circuit. PCB technology offers several advantages over traditional point-to-point wiring, including greater reliability, compactness, and ease of mass production.With the rapid advancement of technology, the demand for smaller, more powerful electronic devices has increased significantly. PCB technology has played a pivotal role in meeting this demand by enabling the development of compact and complex electronic circuits. As a result, electronic devices have become more powerful, efficient, and affordable, driving the growth of the global electronics market.In addition to smaller and more efficient electronic devices, PCB technology has also facilitated the development of advanced electronic systems for various industries. From automotive electronics to medical devices, PCB technology has enabled the production of sophisticated electronic systems that are essential for the advancement of these industries. With the increasing integration of electronics in various applications, the importance of PCB technology in driving innovation and progress cannot be overstated.The continued advancement of PCB technology has also led to the development of more environmentally friendly electronic devices. By enabling the production of smaller and more energy-efficient electronic circuits, PCB technology has contributed to the reduction of electronic waste and the overall environmental impact of electronic devices. As sustainability becomes an increasingly important consideration in the electronics industry, the role of PCB technology in promoting environmental responsibility cannot be ignored.As a leading provider of PCB technology, {} is committed to driving innovation and excellence in the electronics industry. The company's state-of-the-art manufacturing facilities and advanced R&D capabilities enable it to develop cutting-edge PCB solutions that meet the evolving needs of its customers. Through its dedication to quality and innovation, {} has established itself as a trusted partner for companies looking to leverage the power of PCB technology for their electronic products.Moving forward, the future of the electronics industry will continue to be shaped by the advancement of PCB technology. As technology evolves and demand for smaller, more powerful electronic devices grows, the importance of PCB technology in driving innovation and progress will only continue to increase. With companies like {} leading the way, the potential for PCB technology to revolutionize the electronics industry is limitless.

Top 5 PCBA Production Suppliers for OEM Electronics

OEM PCBA Production Suppliers Announcement The highly advanced and respected PCBA manufacturing company, {Company Name}, has announced a significant partnership with top-tier OEM PCBA production suppliers. This partnership is a strategic move by {Company Name} to further expand their product offerings and provide enhanced service and value to their clients. {Company Name} is a leading provider of PCBA (Printed Circuit Board Assembly) manufacturing and assembly services, with a strong reputation for delivering high-quality products to a diverse range of industries. With a focus on providing innovative solutions and exceptional customer service, {Company Name} has become a trusted partner for businesses in need of reliable PCBA production.The partnership with top-tier OEM PCBA production suppliers will further enhance {Company Name}'s capabilities and allow them to offer a wider range of services to their clients. By leveraging the expertise and resources of these suppliers, {Company Name} will be able to meet the increasing demands of their customers while maintaining the highest standards of quality and efficiency.With this collaboration, {Company Name} will be able to offer a more comprehensive range of PCBA production services, including PCB design, component sourcing, assembly, testing, and packaging. This will enable {Company Name} to provide a one-stop solution for businesses seeking a reliable and cost-effective partner for their PCBA manufacturing needs.In addition to expanding their service offerings, the partnership with top-tier OEM PCBA production suppliers will also allow {Company Name} to stay at the forefront of technological advancements in the industry. By working closely with these suppliers, {Company Name} will have access to the latest manufacturing technologies and processes, enabling them to deliver cutting-edge solutions to their clients."We are thrilled to announce our partnership with top-tier OEM PCBA production suppliers," said {Spokesperson} of {Company Name}. "This collaboration will strengthen our position as a leading PCBA manufacturing company and enable us to better serve the evolving needs of our clients. We are committed to delivering superior quality and value to our customers, and this partnership is a testament to that commitment."{Company Name} is known for its commitment to excellence and innovation in the PCBA manufacturing industry. With a team of highly skilled engineers, technicians, and quality control experts, {Company Name} has built a reputation for delivering top-notch products that meet the highest industry standards.The partnership with top-tier OEM PCBA production suppliers is a testament to {Company Name}'s dedication to continuous improvement and customer satisfaction. By aligning with these suppliers, {Company Name} is positioning itself for sustained growth and success in the competitive PCBA manufacturing market.The partnership is expected to have a positive impact on {Company Name}'s ability to meet the diverse needs of their clients, while also opening up new opportunities for growth and expansion. With a focus on delivering exceptional value and service, {Company Name} is well-positioned to continue its trajectory as a leading PCBA manufacturing company in the global market.As {Company Name} continues to innovate and expand its capabilities, it remains committed to providing reliable and cost-effective solutions to businesses in need of high-quality PCBA production services. The partnership with top-tier OEM PCBA production suppliers represents a significant milestone for {Company Name}, and is poised to further enhance their position as a trusted leader in the industry.

Benefits of Using High-Quality PCBs for Your Electronics Projects

High-Quality PCB Company Leads the Way in Circuit Board ManufacturingWith the rapid advancement of technology, printed circuit boards (PCBs) have become an essential component in many electronic devices. From smartphones to automotive systems, PCBs play a crucial role in the functionality of these devices. As the demand for high-quality PCBs continues to rise, companies such as [Company Name] have emerged as leaders in the industry.[Company Name] is a leading manufacturer of high-quality PCBs, specializing in a wide range of products such as rigid, flex, and rigid-flex PCBs. The company has established a strong reputation for delivering top-notch products that meet the highest industry standards. With state-of-the-art facilities and a team of experienced professionals, [Company Name] has positioned itself as a trusted partner for businesses looking for reliable PCB solutions.Founded in [Year], [Company Name] has continuously invested in research and development to stay ahead of the curve in PCB manufacturing. The company's commitment to innovation and quality has enabled them to expand their product offerings and serve a diverse range of industries, including telecommunications, aerospace, medical devices, and more.One of the key factors that set [Company Name] apart from its competitors is its dedication to providing customized solutions to meet the specific needs of its clients. The company works closely with its customers to understand their requirements and deliver tailor-made PCBs that exceed expectations. This personalized approach has earned [Company Name] a loyal customer base and a reputation for excellence in the industry.In addition to its dedication to quality and customer satisfaction, [Company Name] also places a strong emphasis on sustainability and environmental responsibility. The company adheres to strict environmental standards in its manufacturing processes, using eco-friendly materials and practices to minimize its carbon footprint. This commitment to sustainability has not only had a positive impact on the environment but has also resonated with environmentally conscious businesses seeking responsible manufacturing partners.Furthermore, [Company Name] has strategically positioned itself as a global player in the PCB industry, with a strong presence in key markets around the world. By establishing partnerships and alliances with industry leaders, the company has been able to leverage its expertise and expand its reach to new territories, serving a growing customer base worldwide.As the demand for high-quality PCBs continues to grow, [Company Name] remains at the forefront of innovation and excellence in circuit board manufacturing. With a relentless focus on quality, innovation, and customer satisfaction, the company is well-positioned to sustain its leadership in the industry and continue to drive technological advancements in PCB manufacturing.In the ever-evolving landscape of electronics, the need for high-quality PCBs is more crucial than ever. With a strong track record of delivering superior products and a commitment to continuous improvement, [Company Name] stands as a beacon of excellence in the PCB industry.For businesses seeking reliable and innovative PCB solutions, [Company Name] is the partner of choice, offering a comprehensive range of high-quality products and unparalleled customer service. As the company continues to push the boundaries of PCB manufacturing, it remains dedicated to exceeding the expectations of its clients and setting new standards of excellence in the industry.In conclusion, [Company Name] has solidified its position as a leader in the PCB industry through its unwavering commitment to quality, innovation, and customer satisfaction. With its extensive expertise, global reach, and dedication to sustainability, the company is poised to shape the future of circuit board manufacturing and continue to be a driving force in the electronics industry.