Complete Turnkey Assembly Factory Solutions for OEMs

By:Admin

OEM Turnkey Assembly Factories, also known as Original Equipment Manufacturer Turnkey Assembly Factories, are facilities where products or components are manufactured and assembled according to the specifications and designs provided by the client. These factories offer a complete turnkey solution, encompassing everything from design and engineering to manufacturing and assembly, allowing clients to focus on other aspects of their business while the factory handles the production of their products.

One such factory that has been making waves in the industry is {}, a leading provider of OEM Turnkey Assembly services. With state-of-the-art facilities and a team of experienced engineers and technicians, {} has established itself as a reliable partner for businesses looking to outsource their manufacturing and assembly needs.

{}'s turnkey assembly services are tailored to meet the specific requirements of each client. The company works closely with its clients to understand their product designs and specifications, offering valuable input and recommendations to optimize the manufacturing and assembly process. From sourcing high-quality raw materials to precision machining and assembly, {} ensures that each product meets the highest standards of quality and reliability.

One of the key advantages of working with a turnkey assembly factory like {} is the ability to streamline the production process. By outsourcing manufacturing and assembly, businesses can reduce the need for in-house production facilities and equipment, ultimately saving on costs and resources. This also allows businesses to focus on other essential aspects of their operations, such as marketing, sales, and product development.

Additionally, working with a reputable OEM Turnkey Assembly factory can also provide businesses with access to advanced manufacturing technologies and expertise that may not be available in-house. This can lead to improved product quality, faster production times, and ultimately, a competitive edge in the market.

Another benefit of utilizing OEM Turnkey Assembly services is the ability to scale production as needed. Whether a client requires a small batch of products for a limited run or mass production for a large-scale rollout, a turnkey assembly factory can accommodate varying production volumes, ensuring that the client's needs are met efficiently and cost-effectively.

In addition to offering manufacturing and assembly services, {} also provides comprehensive quality control and testing processes to ensure that each product meets the required standards. This includes rigorous testing for functionality, durability, and reliability, as well as adherence to industry-specific regulations and certifications.

As businesses continue to seek cost-effective and efficient solutions for their manufacturing and assembly needs, the demand for OEM Turnkey Assembly services is expected to rise. With their expertise, resources, and capabilities, turnkey assembly factories like {} are well-positioned to meet this growing demand and help businesses streamline their operations while maintaining high quality standards.

In conclusion, OEM Turnkey Assembly Factories play a vital role in today's manufacturing landscape, offering businesses a comprehensive solution for their production needs. By partnering with a reputable turnkey assembly factory like {}, businesses can benefit from enhanced efficiency, cost savings, and access to advanced manufacturing technologies, ultimately helping them stay competitive in the market. With their commitment to quality and customer satisfaction, {} is poised to continue making significant contributions to the industry and help businesses bring their products to market effectively and efficiently.

Company News & Blog

Top Suppliers of High-Quality Chips: Find the Best Options for Your Business

High-Quality Chip Suppliers and Their Impact on the Tech IndustryIn today's tech-driven world, the demand for high-quality chips has never been higher. As technology continues to advance, the need for faster, more efficient, and reliable chips has become essential for a wide range of industries. From smartphones and computers to automotive and healthcare, the role of high-quality chip suppliers is integral in shaping the future of the tech industry.One company that has been making significant strides in the chip manufacturing space is {Company}. {Company} is a leading provider of high-quality chips that are used in a variety of applications, including data centers, automotive, industrial, and consumer electronics. With a strong focus on innovation and cutting-edge technology, {Company} has established itself as a key player in the semiconductor industry.The impact of high-quality chip suppliers like {Company} on the tech industry cannot be overstated. These suppliers play a crucial role in advancing technology and driving innovation across various sectors. Whether it's developing faster processors for smartphones, more efficient power management chips for electric vehicles, or advanced sensors for medical devices, high-quality chip suppliers are at the forefront of driving technological advancements.One of the key factors that set {Company} apart from its competitors is its commitment to producing chips that are not only high-performing but also environmentally sustainable. With a strong emphasis on reducing the environmental impact of chip manufacturing, {Company} is leading the way in developing sustainable solutions that meet the growing demand for eco-friendly technology.Furthermore, {Company} has also been at the forefront of the move towards edge computing, which is focused on processing data closer to the source, rather than relying on centralized data centers. This has become increasingly important with the rise of Internet of Things (IoT) devices, autonomous vehicles, and smart cities, all of which rely on high-quality chips to process and analyze data in real-time.As the demand for high-quality chips continues to grow, suppliers like {Company} are facing new challenges and opportunities. The rapid advancements in artificial intelligence, 5G technology, and quantum computing are driving the need for even more powerful and efficient chips. This presents an exciting opportunity for high-quality chip suppliers to push the boundaries of innovation and meet the evolving needs of the tech industry.Additionally, the global semiconductor shortage has put high-quality chip suppliers in the spotlight, as companies and industries around the world grapple with supply chain disruptions. {Company}, with its strong track record of reliability and quality, has been working tirelessly to mitigate the impact of the shortage and ensure a steady supply of chips to its customers.Looking ahead, the future of high-quality chip suppliers like {Company} looks promising. With a strong focus on sustainability, innovation, and meeting the demands of emerging technologies, {Company} is well-positioned to continue driving the tech industry forward. As the demand for high-quality chips continues to soar, suppliers like {Company} will play an increasingly critical role in shaping the future of technology.In conclusion, high-quality chip suppliers are essential in driving innovation and technological advancements across various industries. With its commitment to sustainability, innovation, and reliability, {Company} is poised to continue making a significant impact on the tech industry for years to come.

Leading Supplier of High-Quality Chips Takes Center Stage in the News

Title: Leading High-Quality Chip Supplier Innovates to Meet Global DemandIntroduction:In today's fast-paced digital age, high-quality and efficient semiconductor chips have emerged as the backbone of numerous industries, including computing, telecommunications, automotive, aerospace, and more. Amid an ever-increasing demand for these chips, companies must continuously innovate to meet customer needs. In this light, one particular high-quality chip supplier stands out with its cutting-edge technology, superior manufacturing processes, and commitment to meeting global demand.Company Background:With a rich history spanning over three decades, this high-quality chip supplier has established itself as a prominent player in the semiconductor industry. At the forefront of technology, the company has consistently pioneered innovations and delivered high-performance chips to address the evolving needs of various sectors around the world. By leveraging their expertise in research and development, the supplier has successfully differentiated itself from competitors and earned a reputation for excellence.Innovation and Technological Advancements:To maintain their leadership position, the chip supplier has consistently invested in research and development activities. This commitment to innovation has enabled the company to produce chips with higher processing speeds, enhanced power efficiency, and increased reliability. By constantly pushing the boundaries of possibility, the supplier guarantees that their clients receive the most advanced solutions available in the market.Additionally, the company embraces a collaborative approach by partnering with technology giants, academia, and startups to leverage a diverse range of perspectives and expertise. By fostering a culture of open innovation, the chip supplier remains at the forefront of new trends, ensuring their products remain compatible with emerging technologies such as artificial intelligence, 5G connectivity, and the Internet of Things (IoT).Manufacturing Excellence and Quality Control:With an unwavering commitment to quality, this high-quality chip supplier operates state-of-the-art manufacturing facilities equipped with the latest equipment and rigorous quality control processes. Every chip undergoes several stages of comprehensive testing to ensure it meets or exceeds industry standards before being shipped to customers. This meticulous attention to detail guarantees that their chips perform impeccably, contributing to the overall success and reliability of the end-products they power.Sustainable Practices:Recognizing the importance of environmental sustainability, the chip supplier has adopted several initiatives to minimize its carbon footprint throughout the manufacturing process. Through investments in energy-efficient manufacturing equipment, waste reduction strategies, and responsible sourcing of materials, the company actively contributes to a greener future.Global Presence and Customer Support:With a robust global distribution network, this high-quality chip supplier serves clients in diverse industries across the world. By maintaining close relationships with customers, the company gains insight into their specific requirements, allowing for tailored chip solutions. Additionally, a dedicated customer support team ensures that clients receive prompt assistance, troubleshooting, and after-sales services, reflecting the supplier's commitment to customer satisfaction.Industry Recognition:The commitment to excellence and innovative advancements by this high-quality chip supplier has earned consistent industry recognition. The company has received numerous awards and accolades for its contributions to the semiconductor industry, including recognition for exceptional product quality, manufacturing excellence, and dedication to customer service.Conclusion:With its unwavering focus on innovation, technological advancements, and customer satisfaction, this high-quality chip supplier continues to make significant contributions to the global semiconductor industry. By consistently delivering high-performance chips and embracing sustainability practices, the company sets new benchmarks for quality and reliability. As demand for semiconductor chips continues to grow across industries, this chip supplier's dedication to meeting customer needs positions it as a leading force in the ongoing digital revolution.

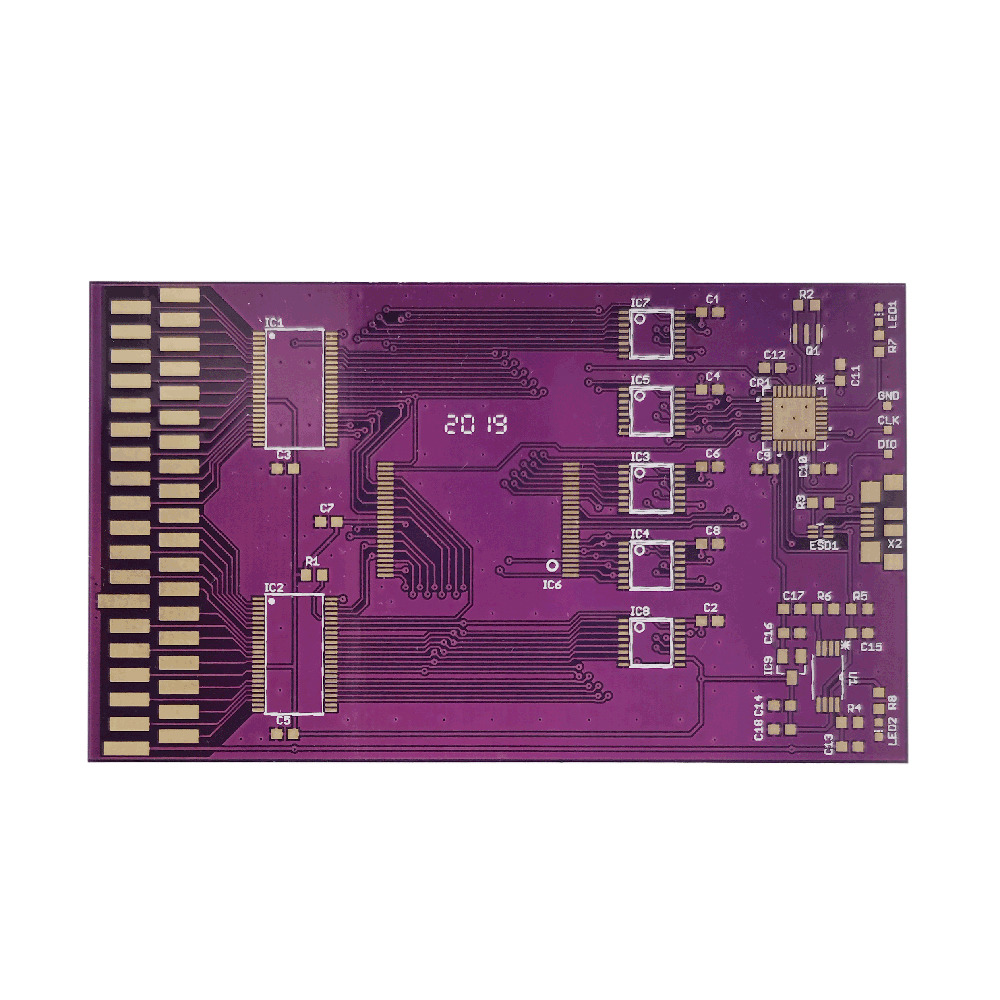

Top 5 PCB Assembly Factories for SMD Electronics

SMD PCB Assembly Factories: The Backbone of Modern Electronics ManufacturingIn the ever-evolving world of electronics manufacturing, SMD PCB assembly factories play a crucial role in ensuring the smooth and efficient production of a wide range of electronic devices. These factories are responsible for the assembly of surface mount device (SMD) printed circuit boards (PCBs), which are integral components in everything from smartphones and computers to industrial machinery and medical devices.One such leading SMD PCB assembly factory is {}, which has established itself as a trusted partner for many global electronics brands. With state-of-the-art facilities and a team of highly skilled technicians, {} has been at the forefront of the SMD PCB assembly industry for over a decade.The process of SMD PCB assembly is complex and requires precision and attention to detail at every step. It involves the placement of electronic components on the surface of the PCB, using advanced pick-and-place machines. These components are then soldered onto the PCB to form a secure electrical connection. This process demands a high level of accuracy and consistency to ensure the reliability and performance of the final electronic device.The demand for SMD PCB assembly services has been steadily increasing, driven by the growing popularity of compact and high-performance electronic products. With the rise of IoT (Internet of Things) technology, there is a greater need for smaller and more efficient electronic components, which can only be achieved through advanced SMD PCB assembly techniques.In response to this growing demand, {} has continuously invested in the latest SMD PCB assembly equipment and technology, ensuring that they are able to meet the needs of their clients in a rapidly changing industry. This commitment to innovation and excellence has earned {} a reputation for delivering high-quality SMD PCB assembly services with a quick turnaround time.Furthermore, {} takes great pride in its strict quality control processes, ensuring that each SMD PCB assembly meets the highest standards for performance and reliability. This dedication to quality has enabled {} to build long-lasting partnerships with clients across a wide range of industries, from consumer electronics to automotive and aerospace.As a leading SMD PCB assembly factory, {} is also committed to sustainable and responsible manufacturing practices. They adhere to strict environmental standards and work towards minimizing their carbon footprint, while also promoting ethical and fair labor practices throughout their supply chain. This dedication to corporate social responsibility has made {} a preferred partner for clients looking for a reliable and ethical SMD PCB assembly provider.With the constant evolution of electronic technology, the role of SMD PCB assembly factories in the manufacturing process will continue to be instrumental. As the demand for smaller, more powerful electronic devices grows, so too will the need for advanced SMD PCB assembly services. Companies like {} are poised to play a key role in meeting this demand, driving innovation and pushing the boundaries of what is possible in the world of electronics manufacturing.

High-Performance Automated SMT Assembly Machine: The Latest Technology in Electronics Manufacturing

Smt Assembly Machine Revolutionizes Electronics ManufacturingIn the ever-evolving world of electronic manufacturing, efficiency and precision are key factors that can make or break a company's success. With the increasing demand for smaller and more advanced electronic devices, the need for state-of-the-art surface mount technology (SMT) assembly machines has never been more crucial. One company that is leading the way in this field is {Company Name}. With their cutting-edge SMT assembly machine, they are revolutionizing the electronics manufacturing industry.{Company Name} has been a leader in the electronics manufacturing industry for over two decades, providing innovative solutions for SMT assembly and production. Their SMT assembly machine is at the forefront of technological advancement, offering unmatched precision, speed, and reliability. This state-of-the-art machine has been designed to meet the demands of modern electronics manufacturing, where components are becoming increasingly smaller and more complex.The SMT assembly machine from {Company Name} utilizes the latest in robotic technology and automated processes to ensure the highest level of accuracy and efficiency. It is equipped with advanced vision systems that can identify and place components with incredible precision, even at high speeds. This level of automation not only increases production output but also minimizes the risk of human error, ultimately leading to higher quality end products.Furthermore, {Company Name} understands the importance of adaptability in the electronic manufacturing industry. Their SMT assembly machine is designed to be easily programmable and reconfigurable, allowing for quick changeovers between product lines and minimizing downtime. This flexibility is crucial in meeting the demands of a rapidly changing market and allows manufacturers to keep up with the latest technological advancements.In addition to the cutting-edge technology, {Company Name} also offers exceptional customer support and service. They work closely with their clients to understand their specific needs and provide customized solutions to meet those needs. Whether it's training, troubleshooting, or ongoing maintenance, {Company Name} is committed to supporting their clients every step of the way.The impact of {Company Name}'s SMT assembly machine on the electronics manufacturing industry cannot be overstated. By streamlining the production process and improving overall efficiency, this machine is helping manufacturers stay competitive in a fast-paced and demanding market. With its advanced technology and unwavering commitment to customer satisfaction, {Company Name} is setting the standard for excellence in electronic manufacturing equipment.In conclusion, {Company Name}'s SMT assembly machine is a game-changer for the electronics manufacturing industry. Its state-of-the-art technology, combined with exceptional customer support, is revolutionizing the way electronic devices are produced. As the demand for smaller and more advanced electronics continues to grow, {Company Name} is at the forefront, providing innovative solutions to meet the industry's evolving needs. With their SMT assembly machine, they are not only setting new standards for efficiency and precision but also driving the future of electronic manufacturing.

Pricing Insights: Exploring the Latest Trends and Factors Impacting PCB Manufacturing Costs

Title: Growth in PCB Manufacturing Price Reflects Industry ExpansionIntroduction:The field of printed circuit board (PCB) manufacturing has witnessed significant growth in recent years, fueled by technological advancements and an increasing demand for electronic devices. Despite facing numerous challenges, the industry has managed to evolve and adapt to changing market trends, contributing to the development of various sectors worldwide. This article delves into the rising prices of PCB manufacturing and highlights the key factors behind this growth.Rising Demand and Technological Advancements:The global electronics market has witnessed a surge in demand for innovative and high-performance electronic devices, including smartphones, wearables, automotive components, and medical devices. With the rapid advancements in technology, these devices require highly sophisticated PCBs that offer improved efficiency, smaller footprints, and enhanced performance.Additionally, the emergence of emerging technologies such as 5G, Internet of Things (IoT), and artificial intelligence (AI) has further fueled the demand for advanced PCBs. These technologies demand complex and multi-layered PCB designs, pushing manufacturers to invest in sophisticated equipment, materials, and processes for production.Increased Material and Production Costs:The rising complexity and requirements of PCBs have led to increased material and production costs. PCB manufacturing involves various resources, including raw materials like copper, laminates, and solder masks, as well as specialized equipment, chemicals, and skilled labor. The prices of these inputs have experienced a steady increase, resulting in higher overall manufacturing costs.Furthermore, the demand for smaller, lightweight, and flexible PCBs has necessitated the use of advanced materials like flex and rigid-flex boards. These materials are more expensive compared to the traditional FR4 substrates, contributing to the rising PCB manufacturing prices.Environmental Regulations and Compliance:In recent years, there has been a growing emphasis on environmental sustainability and regulations concerning hazardous substances. Compliance with environmental standards, such as RoHS (Restriction of Hazardous Substances), has led to the adoption of more eco-friendly manufacturing processes and materials. These modifications come at an increased cost due to the additional efforts required to ensure compliance.Manufacturers have had to invest in new infrastructure, waste management systems, and training to adhere to these regulations. Such measures result in higher expenses during the production process, ultimately impacting the prices of PCB manufacturing.Supply Chain Challenges and Market Volatility:The PCB manufacturing industry heavily relies on a globalized supply chain. Disruptions in the supply chain, such as raw material shortages, geopolitical uncertainties, and transportation constraints, can have a significant impact on production and subsequently affect prices.The ongoing COVID-19 pandemic further highlighted the vulnerability of global supply chains. Factory closures, trade restrictions, and logistic challenges disrupted the supply of essential raw materials, leading to increased costs and delayed deliveries. The need for resilient supply chains to mitigate such risks has compelled manufacturers to invest in diversification and redundancy measures, contributing to the rise in PCB manufacturing prices.Conclusion:The rising prices of PCB manufacturing are a reflection of the industry's response to an increased demand for advanced electronic devices and technologies. Technological advancements, increased material and production costs, compliance with environmental regulations, and supply chain challenges all contribute to the overall increase in manufacturing expenses.Despite these challenges, the PCB manufacturing industry continues to evolve and adapt to market trends, fostering innovation and contributing to the growth of various sectors. Manufacturers are constantly seeking ways to optimize production processes, reduce costs, and improve efficiency, ensuring the delivery of high-quality and cost-effective PCBs to meet the growing demands of consumers worldwide.

The Ultimate Guide to PCB Manufacturing Prices: Everything You Need to Know

Pcb Manufacturing Price: Company Offers Competitive Rates for High-Quality PCBsIn the rapidly evolving world of electronics manufacturing, the demand for high-quality printed circuit boards (PCBs) is higher than ever before. As more and more industries rely on electronic devices and components, the need for reliable and efficient PCBs has become a top priority for manufacturers around the world. In response to this growing demand, {Company Name} is proud to announce that they are offering competitive prices for their top-notch PCB manufacturing services.{Company Name} has been a leading provider of PCB manufacturing and assembly services for over a decade. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, the company is dedicated to delivering high-quality PCBs that meet the exact specifications and requirements of their customers. Whether it's a simple single-layer board or a complex multi-layer design, {Company Name} has the expertise and capabilities to produce PCBs that consistently meet the highest standards of quality and performance.One of the key factors that sets {Company Name} apart from other PCB manufacturers is their commitment to offering competitive prices without compromising on quality. Despite the increasing complexity and sophistication of modern PCB designs, {Company Name} has continually invested in advanced manufacturing technologies and process optimization to streamline production and reduce manufacturing costs. This allows them to offer cost-effective PCB solutions to their customers without sacrificing on reliability or performance.{Company Name} also recognizes the importance of providing flexible and customizable PCB manufacturing services to accommodate the unique needs of their clients. Whether a customer requires quick-turn prototypes, small batch production, or high-volume manufacturing, {Company Name} is capable of delivering PCBs in a timely manner and at a competitive price point. With a focus on customer satisfaction and long-term partnerships, the company is committed to working closely with their clients to provide tailored solutions that meet their specific requirements and budget constraints.In addition to offering competitive pricing, {Company Name} also takes pride in their commitment to quality assurance and compliance with industry standards. Their manufacturing processes and quality control measures are in full conformance with international standards and certifications, ensuring that the PCBs they produce are of the highest quality and reliability. From material selection and manufacturing processes to testing and inspection, {Company Name} follows strict quality protocols to ensure that every PCB meets the stringent requirements of their customers and end-users.Furthermore, {Company Name} maintains a strong focus on continuous improvement and innovation in their manufacturing practices. By staying at the forefront of industry trends and technological advancements, the company is able to leverage the latest advancements in PCB manufacturing to enhance efficiency, precision, and cost-effectiveness. This relentless pursuit of excellence allows {Company Name} to consistently deliver superior PCB products at competitive prices, making them the preferred choice for customers across a wide range of industries.With their unwavering commitment to quality, affordability, and customer satisfaction, {Company Name} is well-positioned to meet the increasing demand for high-quality PCBs in the global market. By offering competitive manufacturing prices for top-notch PCBs, the company aims to become a trusted partner for manufacturers looking to source reliable and cost-effective PCB solutions for their electronic products. As the industry continues to evolve, {Company Name} remains dedicated to providing innovative and reliable PCB manufacturing services that exceed the expectations of their customers and contribute to the advancement of electronic technology.

How Through Hole PCB Technology is Changing the Electronics Industry

The demand for Through Hole PCB (Printed Circuit Board) has been steadily increasing in the electronic manufacturing industry. Through Hole technology is a method of constructing the electronic components on a PCB by inserting the leads of the components through the holes in the board and then soldering them in place. This method provides a strong mechanical bond and reliable electrical connection, making it a preferred choice for many applications.In this context, one company that has been making significant strides in the Through Hole PCB market is {}. {} is a renowned PCB manufacturer with a strong reputation for producing high-quality and reliable PCBs for various industries including aerospace, automotive, medical, and consumer electronics.{} specializes in providing Through Hole PCB solutions that meet the specific requirements of their clients. Their expertise lies in producing PCBs with high thermal and mechanical strength, excellent solderability, and reliable connection points. This makes their Through Hole PCBs suitable for applications that require exceptional durability and performance.The company's state-of-the-art manufacturing facilities are equipped with advanced machinery and technology to ensure the precise and efficient production of Through Hole PCBs. Their team of skilled engineers and technicians are dedicated to maintaining the highest standards of quality and reliability in every PCB they produce.With a commitment to continuous improvement, {} constantly explores new innovations and technologies in Through Hole PCB manufacturing. They invest in research and development to stay ahead of industry trends and to provide their customers with cutting-edge solutions that meet the ever-evolving demands of the market.One of the key advantages of {}'s Through Hole PCBs is their ability to withstand harsh environmental conditions. This makes them suitable for applications that require resistance to extreme temperatures, moisture, and vibration. Additionally, their Through Hole PCBs are designed to support high component density and complex circuitry, making them ideal for advanced electronic devices and systems.Furthermore, {} takes great pride in offering customizable Through Hole PCB solutions that cater to the unique requirements of their clients. Whether it's a prototype, small batch, or large-scale production, they have the capabilities to deliver PCBs that are tailored to specific design specifications and performance standards.In addition to their technical expertise, {} is also committed to providing excellent customer service. They work closely with their clients throughout the entire process, from design and prototyping to production and delivery, ensuring that their needs are met with precision and efficiency.As a leading supplier of Through Hole PCBs, {} has earned the trust and confidence of numerous companies across different industries. Their track record of delivering reliable and high-performance PCB solutions has established them as a preferred partner for businesses seeking top-quality electronic components.In conclusion, the increasing demand for Through Hole PCBs in the electronic manufacturing industry has propelled companies like {} to the forefront of the market. With their focus on quality, innovation, and customer satisfaction, they continue to set new benchmarks in the production of Through Hole PCBs, cementing their position as a trusted leader in the industry.

High-Quality 4 Layer Flex PCB Factories: What You Need to Know

The demand for flexible printed circuit boards (PCBs) has been steadily increasing due to their numerous advantages in electronic applications. In response to this growing demand, 4 Layer Flex PCB Factories has emerged as a leading manufacturer of high-quality flexible PCBs. With a strong commitment to innovation and customer satisfaction, the company has quickly gained recognition in the industry for its reliable and cost-effective PCB solutions.4 Layer Flex PCB Factories specializes in the production of 4-layer flexible PCBs, offering a wide range of design options to meet the specific requirements of their customers. The company utilizes advanced manufacturing technologies and state-of-the-art equipment to ensure the highest level of precision and quality in their products. This commitment to excellence has earned them a reputation for delivering PCBs that consistently meet or exceed industry standards.One of the key advantages of flexible PCBs is their ability to conform to the shape of the device, making them an ideal choice for applications where space is limited. This flexibility also allows for greater design freedom, enabling the integration of complex circuitry into smaller and more compact electronic devices. As a result, 4 Layer Flex PCB Factories has become a preferred supplier for a wide range of industries, including aerospace, medical devices, automotive, and consumer electronics.In addition to their commitment to quality and innovation, 4 Layer Flex PCB Factories is also known for their exceptional customer service. The company works closely with each client to understand their unique requirements and provide tailored solutions to meet their needs. Whether it's a custom design or a high-volume production run, the company's experienced team of engineers and technicians are dedicated to delivering the best possible PCB solutions to their customers.Furthermore, 4 Layer Flex PCB Factories takes great pride in their commitment to environmental sustainability. The company adheres to strict environmental standards in their manufacturing processes, minimizing waste and reducing their carbon footprint. By utilizing eco-friendly materials and energy-efficient practices, the company actively contributes to a cleaner and greener future for the industry.As 4 Layer Flex PCB Factories continues to expand its operations and reach new markets, the company remains focused on staying at the forefront of PCB technology. Through ongoing research and development, they are constantly exploring new ways to enhance the performance and versatility of their flexible PCBs. This dedication to innovation ensures that their customers have access to the most advanced and reliable PCB solutions available.In conclusion, 4 Layer Flex PCB Factories has established itself as a trusted leader in the manufacturing of high-quality flexible PCBs. With a strong emphasis on quality, innovation, customer service, and environmental responsibility, the company has earned the confidence of clients across a wide range of industries. As they continue to grow and evolve, 4 Layer Flex PCB Factories is well-positioned to meet the increasing demand for flexible PCB solutions and maintain their status as a leading provider in the industry.

Top Turnkey PCB Suppliers for OEM Projects

[Company Name] is proud to announce its partnership with OEM turnkey PCB suppliers to further enhance its manufacturing capabilities and meet the growing demand for high-quality printed circuit boards (PCBs). With this collaboration, [Company Name] will be able to offer a wider range of turnkey PCB solutions to its customers, reinforcing its position as a leading provider in the electronics industry.As a leading manufacturer of electronic components, [Company Name] is committed to delivering innovative and reliable products to its customers. With the increasing complexity of electronic devices, the demand for high-quality PCBs has been on the rise. By partnering with OEM turnkey PCB suppliers, [Company Name] aims to expand its capabilities and provide comprehensive solutions to meet the evolving needs of its customers.OEM turnkey PCB suppliers bring a wealth of experience and expertise in the manufacturing of printed circuit boards. Their advanced facilities and state-of-the-art equipment enable them to produce high-quality PCBs with precision and efficiency. By leveraging their capabilities, [Company Name] will be able to offer a wider range of turnkey solutions, including PCB fabrication, assembly, and testing, all under one roof.In addition to enhancing its manufacturing capabilities, the partnership with OEM turnkey PCB suppliers will also enable [Company Name] to streamline its production processes and improve overall efficiency. By leveraging the expertise of its partners, [Company Name] will be able to optimize its operations and deliver products with shorter lead times, ultimately benefiting its customers with faster time to market.Furthermore, the collaboration with OEM turnkey PCB suppliers aligns with [Company Name]'s commitment to quality and reliability. The stringent quality control measures and industry certifications of its partners ensure that the PCBs meet the highest standards and comply with regulatory requirements. This reinforces [Company Name]'s dedication to delivering products that are not only innovative but also adhere to the highest quality standards.The partnership with OEM turnkey PCB suppliers also reflects [Company Name]'s dedication to fostering strong, mutually beneficial relationships within the electronics manufacturing industry. By joining forces with leading suppliers, [Company Name] aims to create a network of partners that can collectively drive innovation and meet the diverse needs of customers across various sectors.With this collaboration, [Company Name] is well-positioned to offer turnkey PCB solutions that are tailored to specific requirements, whether it's for consumer electronics, automotive applications, industrial equipment, or any other sector. The combined expertise of [Company Name] and its partners will enable the company to address the challenges of designing and manufacturing complex PCBs, ultimately providing customers with reliable and cost-effective solutions.As a result of this partnership, [Company Name] looks forward to expanding its footprint in the electronics manufacturing industry and reinforcing its position as a trusted provider of high-quality electronic components. With a broader range of turnkey PCB solutions, [Company Name] aims to meet the evolving needs of its customers and contribute to the advancement of technology across various sectors.In conclusion, the collaboration between [Company Name] and OEM turnkey PCB suppliers marks a significant milestone for the company, as it enhances its manufacturing capabilities and reinforces its dedication to delivering high-quality products. With this partnership, [Company Name] is well-equipped to meet the growing demand for turnkey PCB solutions and drive innovation in the electronics industry.

Top 5 Tips to Find High-Quality PCB Fabricators

High-Quality PCB Fabricator Expands Capabilities to Meet Growing DemandIn the fast-paced world of technology, the demand for high-quality printed circuit boards (PCBs) continues to soar. With the increasing complexity of electronic devices, the need for reliable and efficient PCB fabrication has never been greater. Recognizing this demand, {Company}, a leading PCB fabricator, has announced its expansion of capabilities to meet the growing needs of its customers.{Company} has been in the business of PCB fabrication for over 20 years, earning a reputation for delivering high-quality products and exceptional customer service. The company's commitment to innovation and continuous improvement has positioned it as a trusted provider for a wide range of industries, including automotive, aerospace, telecommunications, and consumer electronics.With its recent expansion, {Company} has invested in state-of-the-art equipment and cutting-edge technologies to enhance its manufacturing capabilities. This investment allows the company to produce PCBs with greater precision, tighter tolerances, and increased complexity, all while maintaining its commitment to quality and reliability.The expansion of capabilities includes the addition of advanced machinery, such as high-speed drilling and routing equipment, automated optical inspection systems, and advanced solder mask application technology. These additions enable {Company} to produce PCBs with finer features, increased density, and improved reliability, meeting the stringent requirements of its customers.Furthermore, the company has expanded its workforce by hiring experienced engineers and technicians who bring a wealth of knowledge and expertise in PCB fabrication. This growth in talent further strengthens {Company}'s ability to provide innovative solutions and technical support to its customers.{Company} has also implemented rigorous quality control measures to ensure that every PCB that leaves its facility meets the highest industry standards. The company adheres to strict inspection protocols and utilizes advanced testing equipment to verify the integrity and performance of its products, giving its customers the confidence that they are receiving the best-in-class PCBs.In addition to its expanded manufacturing capabilities, {Company} has also enhanced its customer support services, offering personalized consultation and support throughout the PCB fabrication process. The company's team of dedicated professionals works closely with its customers to understand their unique requirements and provide tailored solutions to meet their specific needs.The expansion of capabilities at {Company} comes at a time when the demand for high-quality PCBs is at an all-time high. As electronic devices become more sophisticated and technologically advanced, the need for reliable and efficient PCB fabrication has become paramount. {Company}'s commitment to meeting this demand through its expanded capabilities further solidifies its position as a leading provider in the industry.With its investment in advanced technology, talented workforce, and stringent quality control measures, {Company} is well-equipped to continue delivering high-quality PCBs that meet the evolving needs of its customers. The company's dedication to innovation and excellence ensures that it remains at the forefront of the PCB fabrication industry, providing solutions that drive the advancement of technology across various sectors.As {Company} expands its capabilities, it reaffirms its commitment to delivering superior products and services that exceed customer expectations. With a focus on quality, reliability, and innovation, {Company} is poised to continue shaping the future of PCB fabrication and meeting the dynamic needs of the industry.