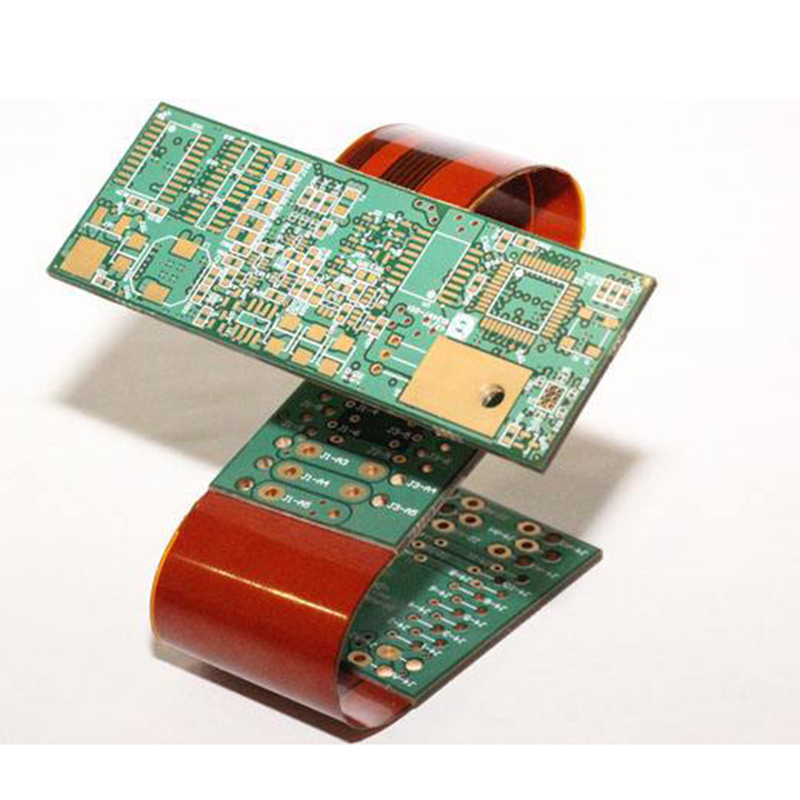

4 Layer Flex PCB Factory - Everything You Need to Know

By:Admin

With a commitment to excellence and innovation, {} has gained a reputation for delivering high-quality PCBs that meet the stringent requirements of its customers. The company prides itself on its state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians who are dedicated to producing superior PCBs.

As an OEM 4 Layer Flex PCB Factory, {} specializes in the production of flexible and rigid-flex PCBs, which are essential components in many electronic devices and systems. These PCBs are designed to be more versatile and durable, making them suitable for applications where traditional rigid PCBs may not be suitable.

One of the key features of {}'s manufacturing process is its ability to produce 4-layer flexible PCBs. This capability allows the company to offer a wide range of options to its customers, including complex and high-density PCB designs. With the ability to produce PCBs with multiple layers, {} can cater to the diverse needs of its clients, ensuring that they receive customized solutions that meet their specific requirements.

{}'s commitment to quality is evident in its rigorous quality control processes and adherence to international standards. The company ensures that every PCB it produces undergoes thorough testing and inspection to guarantee its reliability and performance. This attention to detail has earned {} the trust and loyalty of its customers, who rely on the company for their PCB needs.

In addition to its technical capabilities, {} also prides itself on its customer-centric approach. The company works closely with its clients to understand their unique requirements and provide tailored solutions that meet their needs. Whether it's a prototype development or a large-scale production run, {} is dedicated to delivering exceptional service and support to its customers.

With the increasing demand for high-quality PCBs, {} has positioned itself as a reliable partner for businesses looking for a trusted OEM 4 Layer Flex PCB Factory. The company's ability to offer advanced PCB solutions, combined with its commitment to quality and customer satisfaction, has set it apart in the industry.

Looking ahead, {} is poised to continue its growth and expansion, driven by its commitment to innovation and excellence. The company's investment in cutting-edge technology and talent will enable it to meet the evolving needs of the market and maintain its position as a leader in the PCB manufacturing industry.

In conclusion, {}'s reputation as a leading OEM 4 Layer Flex PCB Factory is well-deserved, thanks to its dedication to quality, innovation, and customer satisfaction. As the demand for high-quality PCBs continues to grow, {} is well-positioned to meet the needs of its clients and contribute to the advancement of various industries that rely on cutting-edge electronic technologies.

Company News & Blog

Discover the Advantages of Fast PCB Assembly Services for Streamlined Production

XYZ Electronics Expands Its PCB Assembly Factory to Meet Growing Market Demand[City], [Date] - XYZ Electronics, a leading player in the electronics manufacturing industry, announced today that it is expanding its state-of-the-art PCB assembly factory to cater to the rising demand for its products. This move comes as a part of XYZ Electronics' strategic plan to consolidate its position as a reliable and efficient provider of cutting-edge electronic solutions.The decision to expand the factory was driven by the company's continuous efforts to meet the increasing market demand for high-quality PCB assembly services. With technological advancements, the demand for electronic devices is skyrocketing, and XYZ Electronics is well-prepared to serve this growing market segment.The expanded factory will enable XYZ Electronics to ramp up its production capacity significantly. The company has invested heavily in new equipment and machinery to ensure streamlined manufacturing processes and improve overall efficiency. With the addition of advanced automated assembly lines, XYZ Electronics now has the capability to assemble a wide range of circuit board designs with utmost precision and speed.Furthermore, the company's commitment to quality has also driven the expansion project. XYZ Electronics adheres to stringent quality control measures to ensure that every product leaving the factory is flawless. The newly expanded factory will allow the company to maintain its high standards and deliver flawless PCB assemblies to its customers consistently.The expansion project also emphasizes XYZ Electronics' dedication to sustainability and environmental responsibility. The company has implemented various eco-friendly measures in their manufacturing processes. These measures include recycling programs, energy-efficient machinery, and the use of environmentally friendly materials. By expanding its factory, XYZ Electronics aims to further reduce its carbon footprint and contribute to a greener future.In addition to meeting market demands, the expansion also creates employment opportunities for the local community. The new facility has created several job positions, ranging from skilled technicians to production line workers. XYZ Electronics believes in fostering a sense of community and providing employment opportunities for local talent.Mr. [Name], CEO of XYZ Electronics, expressed his enthusiasm about the expansion, stating, "This expansion highlights our commitment to continuously improving our services and meeting the evolving needs of our customers. With this larger facility, we will be able to serve a wider customer base and cater to their requirements promptly. We are confident that the expanded factory will solidify our position as a leading provider of PCB assembly services."The improved capabilities of the factory will undoubtedly benefit XYZ Electronics' existing customer base, which includes a wide range of industries such as aerospace, telecommunications, automotive, and medical devices. The company's extended capabilities will allow it to take on more significant projects, both in terms of volume and complexity, effectively catering to the diverse needs of its clients.As XYZ Electronics expands its PCB assembly factory, it demonstrates its commitment to staying at the forefront of the electronics manufacturing industry. With increased production capacity, advanced assembly techniques, and a focus on quality and sustainability, XYZ Electronics is well-positioned to meet the challenges and demands of the ever-evolving electronics market.

Top Quality PCBA Manufacture Factory in China Offers Cutting-Edge Services

[Title]: China PCBA Manufacturer Continues to Innovate and Expand Production Capacities[Subtitle]: Leading Electronics Manufacturing Company Expands its Operations to Meet Growing Demand[Company Name], a renowned PCBA (Printed Circuit Board Assembly) manufacturer, is making waves in the electronics manufacturing industry as it continues to innovate and expand its production capacities in response to a surging demand for electronic devices and components. With its constant commitment to quality, efficiency, and customer satisfaction, the company has solidified its position as a trusted manufacturer both domestically and internationally.Established in [year], [Company Name] has consistently stayed ahead of the curve, offering cutting-edge PCBA solutions to various industries, including telecommunications, automotive, consumer electronics, medical devices, and more. With an extensive range of services, including PCB design, component sourcing, PCB assembly, and testing, the company has earned a reputation for its comprehensive capabilities and end-to-end solutions.One of the key factors contributing to [Company Name]'s success is its state-of-the-art manufacturing facilities. The company has recently invested heavily in expanding its production capacities, ensuring it stays at the forefront of the rapidly evolving electronics landscape. By incorporating the latest technology and automated systems, [Company Name] guarantees streamlined processes, reduced lead times, and enhanced product quality.Moreover, [Company Name] is committed to sustainability and eco-friendly practices. The company's manufacturing processes adhere to strict environmental regulations, focusing on energy efficiency, waste reduction, and responsible disposal of hazardous materials. By implementing green initiatives throughout its operations, [Company Name] not only contributes to a more sustainable future but also addresses the growing demand for environmentally conscious manufacturing practices.In addition to its robust manufacturing capabilities, [Company Name] places great emphasis on research and development to stay at the forefront of technological advancements. The company's dedicated team of engineers and technicians constantly work on innovative solutions to meet the evolving needs of its diverse clientele. By collaborating closely with its customers, [Company Name] ensures that its products and services align with the industry's ever-changing requirements.Furthermore, to enhance its global presence, [Company Name] has strategically established partnerships with leading companies and distributors worldwide. By forming strong alliances, the company expands its reach and offers efficient delivery options to customers around the globe. These partnerships also enable [Company Name] to tap into new markets and stay attuned to regional demands, making it a truly global player in the electronics manufacturing sector.Customer satisfaction lies at the core of [Company Name]'s business philosophy. The company understands the value of delivering exceptional quality and meeting strict deadlines. By implementing rigorous quality control measures at every stage of the manufacturing process, [Company Name] ensures that every product leaving its facilities meets the highest industry standards. This commitment to quality has earned the company numerous certifications and accolades, solidifying its reputation as a trusted manufacturer.As the demand for electronic devices and components continues to surge, [Company Name] remains dedicated to its mission of providing exemplary PCBA solutions. By expanding its manufacturing capacities, incorporating cutting-edge technology, and establishing strategic partnerships, the company is prepared to meet the demands of an ever-evolving industry. With its unwavering commitment to innovation and customer satisfaction, [Company Name] is poised to maintain its leading position in the global PCBA manufacturing market.In conclusion, China's leading PCBA manufacturer, [Company Name], continues to make strides in the electronics manufacturing industry. Through its commitment to quality, sustainability, and innovation, the company is well-positioned to meet the growing demand for electronic devices and components. With its expanded production capacities, extensive service offerings, and strong global presence, [Company Name] remains at the forefront of the sector, shaping the future of PCBA manufacturing.

The Benefits of Prototype PCB Assembly for Your Manufacturing Needs

Prototype PCB Assembly Factory Sets New Industry Standard[City], [Date] – The leading prototype PCB assembly factory in the industry, [Company Name], has recently announced the launch of their state-of-the-art assembly facility. The new facility is set to revolutionize the way prototype PCBs are manufactured, setting a new industry standard for quality, efficiency, and innovation.With over [number] years of experience in the PCB assembly industry, [Company Name] has built a reputation for delivering high-quality, reliable, and cost-effective assembly services. Their commitment to continuous improvement and innovation has led them to invest in the development of their new facility, which is equipped with the latest technologies and manufacturing processes.One of the key features of the new facility is its advanced automated assembly line, which is capable of producing prototype PCBs with unmatched precision and efficiency. This new technology allows [Company Name] to meet the growing demand for high-quality prototype PCBs while reducing lead times and costs for their customers.In addition to the advanced assembly line, the new facility also boasts a dedicated quality control department that is staffed by a team of experienced engineers and technicians. This team is responsible for ensuring that all prototype PCBs manufactured at the facility meet the highest quality standards, providing customers with peace of mind and confidence in the reliability of their products.Furthermore, the new facility is designed to be environmentally friendly, with a focus on reducing waste and energy consumption. By implementing eco-friendly manufacturing processes and sustainable practices, [Company Name] is demonstrating its commitment to environmental responsibility and sustainability.To celebrate the launch of the new facility, [Company Name] is offering special incentives to customers who place their prototype PCB assembly orders within the first [number] of months. These incentives include discounted pricing, expedited lead times, and priority access to the new facility’s capabilities.The company's representative, [Name], shared his excitement about the new facility, stating, "We are thrilled to introduce our new prototype PCB assembly facility to the industry. This investment represents our ongoing commitment to providing our customers with the best possible manufacturing solutions, and we are confident that it will set a new standard for quality, efficiency, and innovation in the industry."With the launch of their new facility, [Company Name] is poised to solidify its position as a leader in the prototype PCB assembly industry, and is prepared to meet the increasing demand for high-quality, reliable prototype PCBs. Their dedication to continuous improvement and innovation is evident in the development of this new facility, and it is sure to have a significant impact on the industry as a whole.

Advanced Soldering Technology: Latest Developments in Joining Materials

[Company Name], a leading manufacturer and supplier of electronic components, has recently announced a breakthrough in soldering technology that is set to revolutionize the industry. The company's innovative new soldering technique is poised to deliver significant improvements in efficiency and performance, offering a game-changing solution for electronic manufacturers and designers.The newly developed soldering technology, which the company has chosen not to disclose, promises to address many of the key challenges that electronic manufacturers have been facing. By significantly enhancing the reliability and strength of solder joints, the new technology is expected to improve the overall quality and durability of electronic products. This will not only benefit manufacturers and designers but will also have a positive impact on end-users who rely on electronic devices in their everyday lives.In addition to improved quality, the new soldering technology also offers substantial efficiency gains. By streamlining the soldering process and reducing the time required for each joint, manufacturers can expect to see a noticeable increase in productivity. This, in turn, will lead to cost savings and a more competitive position in the market.The development of this groundbreaking technology has been the result of extensive research and development efforts by [Company Name]. With a dedicated team of experts and state-of-the-art facilities, the company has been able to push the boundaries of traditional soldering methods and develop a truly cutting-edge solution. The company's commitment to innovation and excellence has been the driving force behind this achievement, and it is a testament to their position as a leader in the electronic components industry.Furthermore, [Company Name] has emphasized that their new soldering technology has been designed with environmental sustainability in mind. By minimizing material waste and energy consumption, the new technique aligns with the company's broader commitment to eco-friendly practices. This ensures that the benefits of the technology extend beyond performance and efficiency, making it a responsible choice for the industry as a whole.The unveiling of this new soldering technology marks an important milestone for [Company Name], as they continue to lead the way in shaping the future of electronic manufacturing. With a strong track record of delivering innovative solutions and a dedication to meeting the needs of their customers, the company is well-positioned to make a significant impact with this latest advancement.In response to the announcement, industry experts and stakeholders have expressed enthusiasm and anticipation for the potential impact of the new soldering technology. Many have highlighted the potential for higher quality products, improved production processes, and a more sustainable approach to manufacturing. It is clear that [Company Name]'s new soldering technology is poised to have far-reaching implications for the electronic components industry.As the company prepares to roll out the new technology, they have emphasized their commitment to providing comprehensive support and resources to their customers. This includes training, technical assistance, and ongoing communication to ensure a smooth transition to the innovative soldering technique. For manufacturers and designers seeking to leverage the benefits of the new technology, [Company Name] is well-prepared to offer the necessary guidance and expertise.Overall, the introduction of this new soldering technology by [Company Name] represents a significant advancement for the electronic components industry. By offering a solution that enhances quality, efficiency, and sustainability, the company is poised to make a lasting impact and set new standards for the industry. With their dedication to innovation and customer satisfaction, [Company Name] is well-positioned to drive positive change and shape the future of electronic manufacturing.

High-quality glass fiber material used in new technology

The use of FR-4 glass fiber material in a wide range of industries has been gaining momentum in recent years. This versatile material has become a staple in the production of various products, thanks to its exceptional strength, durability, and resistance to heat and chemicals. {Company}, a leading manufacturer and supplier of FR-4 glass fiber material, has been at the forefront of this trend, providing high-quality and innovative solutions to its customers.The FR-4 glass fiber material, often referred to as epoxy fiberglass, is a type of composite material formed by reinforcing a plastic matrix with glass fibers. This process creates a material that is both lightweight and incredibly strong, making it an ideal choice for applications in industries such as electronics, automotive, aerospace, and construction.One of the key features of FR-4 glass fiber material is its high-temperature resistance. This makes it suitable for use in printed circuit boards (PCBs), where it serves as the base material for mounting electronic components. The material's ability to withstand high temperatures ensures the longevity and reliability of the PCBs, making it an essential component in modern electronic devices.In the automotive industry, FR-4 glass fiber material is utilized in the production of various structural and interior components. Its high strength-to-weight ratio and resistance to chemical corrosion make it an ideal material for manufacturing parts such as engine covers, door panels, and interior trim components. Additionally, its thermal insulation properties make it suitable for use in exhaust system components and under-the-hood applications.In the aerospace industry, FR-4 glass fiber material is used in the construction of aircraft interiors, as well as for structural components such as wing spars and fuselage panels. Its lightweight nature and exceptional strength make it an essential material for meeting the stringent requirements of the aerospace industry, where weight savings and durability are critical factors.{Company}, a renowned manufacturer and supplier of FR-4 glass fiber material, has been instrumental in advancing the use of this material across various industries. With state-of-the-art manufacturing facilities and a dedicated research and development team, the company has been able to consistently deliver high-quality and innovative solutions to its customers.The company's commitment to quality and innovation has earned it a reputation as a trusted partner for businesses seeking high-performance materials. Its extensive product range and custom manufacturing capabilities have made it a preferred supplier for companies operating in diverse industries, including electronics, automotive, aerospace, and construction.{Company}'s focus on sustainability and environmental responsibility is another factor that sets it apart in the industry. The company adheres to strict environmental standards in its manufacturing processes and is committed to reducing its carbon footprint. Additionally, its products are designed for longevity and recyclability, further contributing to its environmentally friendly practices.Moving forward, {Company} is poised to continue its leadership in the FR-4 glass fiber material market, with a strong emphasis on research and development. The company is constantly exploring new applications and technologies to push the boundaries of what is possible with this versatile material. Its partnerships with industry leaders and commitment to customer satisfaction further position it as a key player in the global market.In conclusion, the use of FR-4 glass fiber material has become indispensable in modern manufacturing, thanks to its exceptional strength, durability, and resistance to heat and chemicals. {Company} has been a driving force in advancing the use of this material across various industries, providing high-quality and innovative solutions to its customers. With a strong focus on research and development, sustainability, and customer satisfaction, the company is well-positioned to continue its leadership in the FR-4 glass fiber material market.

Leading Digital PCB Suppliers for OEMs: High-Quality Circuit Boards

OEM Digital PCB Suppliers, a leading provider of digital printed circuit boards, has recently announced its partnership with a well-established technology company. This partnership aims to further enhance the capabilities and reach of both companies within the digital PCB industry. With their combined expertise and resources, they are set to deliver innovative solutions for a wide range of applications, including consumer electronics, automotive, medical devices, and more.OEM Digital PCB Suppliers is a renowned name in the industry, known for their high-quality PCBs and reliable services. With a strong focus on technological advancement and customer satisfaction, they have built a reputation for delivering cutting-edge solutions to their clients. Their state-of-the-art facilities and advanced manufacturing processes have enabled them to meet the evolving demands of the digital PCB market, while ensuring the highest standards of quality and reliability.The company takes pride in its ability to cater to the unique requirements of each client, offering custom solutions that are tailored to specific needs. Whether it's a complex multilayer PCB for a high-end electronic device or a simple single-layer board for a prototype, OEM Digital PCB Suppliers has the expertise and resources to deliver the perfect solution. Their commitment to innovation and continuous improvement has enabled them to stay ahead of the competition and establish themselves as a trusted partner for numerous technology companies.The recent partnership with the technology company is a significant development for OEM Digital PCB Suppliers, as it opens up new opportunities for collaboration and growth. By leveraging the technology company's resources and market presence, OEM Digital PCB Suppliers aims to expand its reach and explore new market segments. This partnership also aligns with their strategic vision of staying at the forefront of technological advancements and offering the best-in-class solutions to their clients.The technology company, on the other hand, stands to benefit from OEM Digital PCB Suppliers' expertise in the digital PCB industry. With access to their advanced manufacturing capabilities and proven track record of delivering high-quality PCBs, the technology company can enhance the performance and reliability of their own products. This partnership is a testament to the mutual trust and confidence that both companies have in each other's capabilities, and it is expected to result in a fruitful and productive collaboration.One of the key objectives of the partnership is to drive innovation in the digital PCB industry and bring forth new solutions that address the evolving needs of the market. By pooling their resources and expertise, the two companies can explore new technologies and design methodologies that can push the boundaries of what is possible with digital PCBs. This includes advancements in materials, manufacturing processes, and design techniques that can lead to more efficient and reliable PCBs for a wide range of applications.Furthermore, the partnership is expected to result in a more streamlined and efficient supply chain for digital PCBs. By working closely together, the companies can optimize their production processes, reduce lead times, and improve overall cost efficiencies. This will ultimately benefit their clients, as they can expect faster turnaround times and more competitive pricing for their digital PCB requirements.As the partnership between OEM Digital PCB Suppliers and the technology company takes shape, both parties are excited about the prospects of what they can achieve together. With a shared vision of excellence and a commitment to pushing the boundaries of innovation, they are poised to make a significant impact in the digital PCB industry. By leveraging their collective strengths and resources, they are set to deliver groundbreaking solutions that will shape the future of digital electronics.

Top Suppliers of OEM Printed Circuit Boards Reveal New Market Trends

OEM Printed Board Suppliers Poised to Revolutionize the Electronics IndustryThe electronics industry is on the cusp of a revolution with the emergence of a new player in the market, OEM Printed Board Suppliers. With years of experience and expertise in the field, this revolutionary company is set to transform the way electronic components are manufactured and revolutionize the industry as a whole.OEM Printed Board Suppliers, with their state-of-the-art facilities and cutting-edge technology, are equipped to handle the increasing demands of the electronics industry. With an expansive range of services, they offer end-to-end solutions for all printed circuit board (PCB) needs. From design and prototyping to production and assembly, the company ensures top-notch quality and performance of their products.One of the key factors that set OEM Printed Board Suppliers apart from their competitors is their commitment to innovation and continuous improvement. They consistently invest in research and development to stay ahead of the curve and offer their clients the latest advancements in PCB technology. By keeping a close eye on emerging trends and market demands, they are able to provide tailor-made solutions to cater to the ever-evolving needs of their clients.With a firm belief in sustainable practices, OEM Printed Board Suppliers prioritize environmental conservation. They strive to minimize waste, reduce energy consumption, and adopt eco-friendly manufacturing processes. By using the most advanced and efficient equipment, they ensure minimal impact on the environment while delivering superior products.The company's dedication to customer satisfaction is evident in their customer-centric approach. They collaborate closely with their clients, taking into account their specific requirements, budgets, and timelines. OEM Printed Board Suppliers offer personalized solutions to suit each client's unique needs, ensuring a seamless experience from start to finish.Furthermore, OEM Printed Board Suppliers boast a team of highly skilled professionals who are experts in their respective fields. From engineers and designers to technicians and quality control personnel, each member of their team plays a crucial role in delivering exceptional products. With their vast knowledge and experience, the team ensures that every project is executed with precision and attention to detail.In addition to their commitment to quality, innovation, sustainability, and customer satisfaction, OEM Printed Board Suppliers also prioritize affordability. They understand the importance of cost-effective solutions in the highly competitive electronics industry and offer competitive pricing without compromising on the quality of their products.This revolutionary company has quickly established itself as a reliable and trusted partner for electronics manufacturers worldwide. With their expertise and state-of-the-art facilities, OEM Printed Board Suppliers have become a go-to solution for companies looking for top-quality printed circuit boards.As the electronics industry continues to grow at an exponential rate, OEM Printed Board Suppliers are well-positioned to meet the increasing demands. Their commitment to innovation, sustainability, customer satisfaction, and affordability sets them apart from their competitors and ensures their continued success in the industry.In conclusion, OEM Printed Board Suppliers are on a mission to revolutionize the electronics industry. With their advanced technology, commitment to innovation, sustainable practices, customer-centric approach, skilled professionals, and competitive pricing, they are set to transform the way electronic components are manufactured. As they continue to grow and adapt to the evolving needs of the market, OEM Printed Board Suppliers are poised to become the leading players in the industry, driving the future of electronics manufacturing.

Top 5 Circuit PCB Suppliers in China: A Comprehensive Guide

China Circuit PCB Suppliers Expand Production Capacity to Meet Growing DemandIn response to the increasing demand for high-quality printed circuit boards (PCBs), China-based circuit PCB suppliers have announced a significant expansion of their production capacity. The move is aimed at meeting the growing demand from various industries, including consumer electronics, automotive, aerospace, and telecommunications.One of the leading circuit PCB suppliers in China, [Company Name], has recently completed a major expansion of its production facilities. With the new production lines and advanced equipment, the company aims to enhance its manufacturing capabilities and meet the increasing needs of its global customer base.[Company Name] has been a trusted supplier of high-performance PCBs for over a decade. The company's commitment to quality, innovation, and customer satisfaction has positioned it as a preferred supplier for many leading companies in the electronics industry. With the expansion of its production capacity, [Company Name] is poised to further strengthen its position in the market and cater to the evolving needs of its customers.The expansion of production capacity comes at a time when the demand for high-quality PCBs is on the rise. As electronic devices become more advanced and sophisticated, the need for reliable and efficient PCBs has become increasingly important. This trend is particularly evident in the consumer electronics sector, where products such as smartphones, tablets, and wearable devices rely on high-performance PCBs for their functionality and performance.In addition to consumer electronics, the automotive industry is also driving the demand for advanced PCBs. With the growing adoption of electric vehicles and autonomous driving technologies, automotive manufacturers are seeking PCBs with higher power density, thermal performance, and reliability. This has created a significant opportunity for circuit PCB suppliers to provide innovative solutions that meet the stringent requirements of the automotive industry.Furthermore, the aerospace and telecommunications sectors are also key drivers of demand for high-quality PCBs. With the increasing deployment of satellite communications, 5G networks, and IoT (Internet of Things) devices, the need for robust and reliable PCBs has never been greater. Circuit PCB suppliers that can deliver cutting-edge solutions for these applications are well positioned to capitalize on the growing market opportunities.[Company Name]'s expansion of production capacity underscores its commitment to meeting the diverse needs of its customers across various industries. By investing in state-of-the-art manufacturing facilities and advanced technologies, the company aims to deliver superior PCB products that can enable the next generation of electronic devices and systems.In addition to expanding its production capacity, [Company Name] is also focused on enhancing its capabilities in research and development. The company's team of experienced engineers and technical experts are dedicated to exploring new materials, processes, and design techniques to further improve the performance and reliability of its PCBs.As a responsible circuit PCB supplier, [Company Name] is also mindful of the environmental impact of its operations. The company adheres to strict environmental standards and incorporates sustainable practices in its manufacturing processes. By minimizing waste and optimizing energy efficiency, [Company Name] is committed to minimizing its carbon footprint and contributing to a greener and more sustainable future.In conclusion, the expansion of production capacity by circuit PCB suppliers in China is a positive development that reflects the growing demand for high-quality PCBs across various industries. With their enhanced manufacturing capabilities and focus on innovation, companies like [Company Name] are well positioned to address the evolving needs of their customers and contribute to the advancement of electronic technology. As the demand for advanced electronic devices continues to grow, the role of circuit PCB suppliers in enabling these technologies will only become more crucial in the years to come.

High-Quality Surface Mount PCB Assembly Services for Your Business

In the fast-paced and ever-evolving world of electronics manufacturing, the demand for high-quality and reliable printed circuit board (PCB) assembly services is at an all-time high. As electronic devices become smaller, more advanced, and more integral to our daily lives, the need for precise and efficient PCB assembly has become paramount. This is where {Company Name}, a leading provider of advanced electronics manufacturing services, comes into play.{Company Name} is a key player in the electronics manufacturing industry, specializing in a wide range of services including PCB assembly, box build assembly, and electronics design. With state-of-the-art facilities and a team of experienced and highly-skilled professionals, {Company Name} has earned a reputation for delivering superior quality and unmatched reliability in every project they undertake.One of {Company Name}'s core competencies is surface mount PCB assembly, a technique that has revolutionized the way electronic devices are designed and manufactured. Surface mount technology (SMT) allows for the mounting of electronic components directly onto the surface of the PCB, as opposed to through-holes, resulting in a much more compact and efficient assembly process. This advancement has paved the way for smaller, lighter, and more powerful electronic devices, and {Company Name} has been at the forefront of harnessing the full potential of SMT.{Company Name}'s surface mount PCB assembly capabilities are second to none, and they have the expertise and technology to handle even the most complex and intricate assembly projects. With advanced pick-and-place machines, automated soldering equipment, and stringent quality control measures, {Company Name} ensures that every PCB assembly meets the highest standards of precision and reliability.One of the key advantages of {Company Name}'s surface mount PCB assembly services is their ability to handle high-volume production with quick turnaround times. This is especially crucial in today's fast-paced electronics market, where time-to-market is a critical factor in a product's success. {Company Name} understands the importance of efficiency and agility in PCB assembly, and they have optimized their processes to ensure rapid and cost-effective production without compromising on quality.Furthermore, {Company Name} pays meticulous attention to detail in every step of the PCB assembly process, from component sourcing and inspection to soldering and testing. Their commitment to excellence has earned them the trust and loyalty of a wide range of clients, including leading technology companies, startups, and innovators across various industries.In addition to their technical prowess, {Company Name} takes pride in their customer-centric approach, working closely with clients to understand their unique requirements and provide tailored solutions that meet their specific needs. Whether it's a prototype for a groundbreaking new gadget or a large-scale production run of a consumer electronics device, {Company Name} is dedicated to delivering the highest quality PCB assembly services with an unwavering focus on customer satisfaction.With a track record of success and a dedication to innovation, {Company Name} is poised to remain a driving force in the electronics manufacturing industry, particularly in the realm of surface mount PCB assembly. As technology continues to advance and the demand for smaller, smarter, and more efficient electronic devices grows, {Company Name} is well-equipped to lead the way with their cutting-edge PCB assembly capabilities.In conclusion, {Company Name} stands as a testament to the potential of surface mount PCB assembly and its transformative impact on the electronics industry. By leveraging their expertise, state-of-the-art facilities, and unwavering commitment to quality, {Company Name} continues to be a trusted partner for clients seeking the very best in PCB assembly services. With an eye toward the future, {Company Name} is poised to remain at the forefront of innovation and excellence in electronics manufacturing.

Revolutionizing Electronics: Unleashing the Power of Flexible PCB Technology

[Company Introduction]{Insert Company Name}, a leading manufacturer in the electronics industry, is revolutionizing the market with its innovative flexible printed circuit boards (PCBs). With years of experience and a dedicated team of experts, {Company Name} has established itself as a go-to provider of high-quality and reliable flexible PCB solutions globally.{Company Name} prides itself on its commitment to innovation and technology-driven manufacturing processes. The company utilizes state-of-the-art machinery, advanced materials, and cutting-edge techniques to develop flexible PCBs that meet even the most demanding requirements of various industries, such as automotive, consumer electronics, medical devices, and telecommunications.With a focus on sustainability, {Company Name} places a strong emphasis on environmental responsibility throughout its manufacturing process. By adhering to strict guidelines and regulations, the company ensures the production of flexible PCBs that are eco-friendly and leave a minimal carbon footprint.[News Content]Title: {Company Name} Unveils Groundbreaking Flexible PCB Technology Subtitle: Revolutionary Flexible PCBs Poised to Reshape the Electronics Industry{City, Date} - With an aim to redefine the electronics industry, {Company Name} announced the release of its groundbreaking flexible PCB technology, poised to revolutionize the way we approach electronic design and manufacturing.Flexible PCBs, also known as Flex PCBs, are highly versatile printed circuit boards that offer exceptional flexibility and durability. Unlike traditional rigid PCBs, these flexible counterparts can be bent, folded, and twisted without compromising the circuit's functionality. This flexibility makes them ideal for applications where space is limited or irregular shapes are involved.{Company Name}'s flexible PCBs incorporate state-of-the-art materials and manufacturing techniques, ensuring exceptional performance and reliability. By combining high-quality materials with advanced technologies, the company has achieved a significant milestone in the development of flexible PCBs.One of the key advantages of {Company Name}'s flexible PCB technology is its ability to reduce manufacturing costs and complexity. The flexibility of these PCBs eliminates the need for complex wiring and connectors, thus streamlining the production process and reducing the overall assembly time. This breakthrough technology not only simplifies manufacturing but also ensures enhanced durability and functionality of electronic devices.Furthermore, the unique properties of flexible PCBs allow for efficient heat dissipation. This makes them an excellent choice for high-power applications, such as automotive electronics and power electronics, where heat management plays a crucial role in maintaining optimal performance and longevity.In addition to their flexibility and durability, {Company Name}'s flexible PCBs also offer exceptional resistance to vibration and shock. This resilience makes them ideal for various industries, including aerospace, defense, and medical devices, where reliability and stability are paramount.{Company Name} is committed to meeting the evolving needs of its customers. With a comprehensive range of innovative designs and customization options, the company ensures that its flexible PCBs are tailored to specific application requirements. This level of versatility empowers engineers and designers to explore new possibilities and push the boundaries of electronic design.{Company Name} has also invested significantly in its research and development division, continuously striving to improve its flexible PCB technology. The company's relentless pursuit of innovation and quality has gained industry-wide recognition and solidified its position as a leading provider of flexible PCB solutions.As the demand for smaller, more flexible electronic devices continues to grow, {Company Name}'s flexible PCBs are positioned to reshape the industry and empower manufacturers to create cutting-edge products. With a commitment to sustainability, technological advancement, and customer satisfaction, {Company Name} is set to revolutionize electronic design and manufacturing with its breakthrough flexible PCB technology.About {Company Name}:{Insert Company Name} is a renowned electronics manufacturer specializing in the production of flexible PCBs. With a focus on innovation and sustainability, the company is dedicated to delivering high-quality, reliable, and customizable flexible PCB solutions to customers worldwide. Through continuous research and development, {Company Name} strives to push the boundaries of electronic design and support the advancement of technology across various industries.