High-speed PCB assembly factories: What you need to know

By:Admin

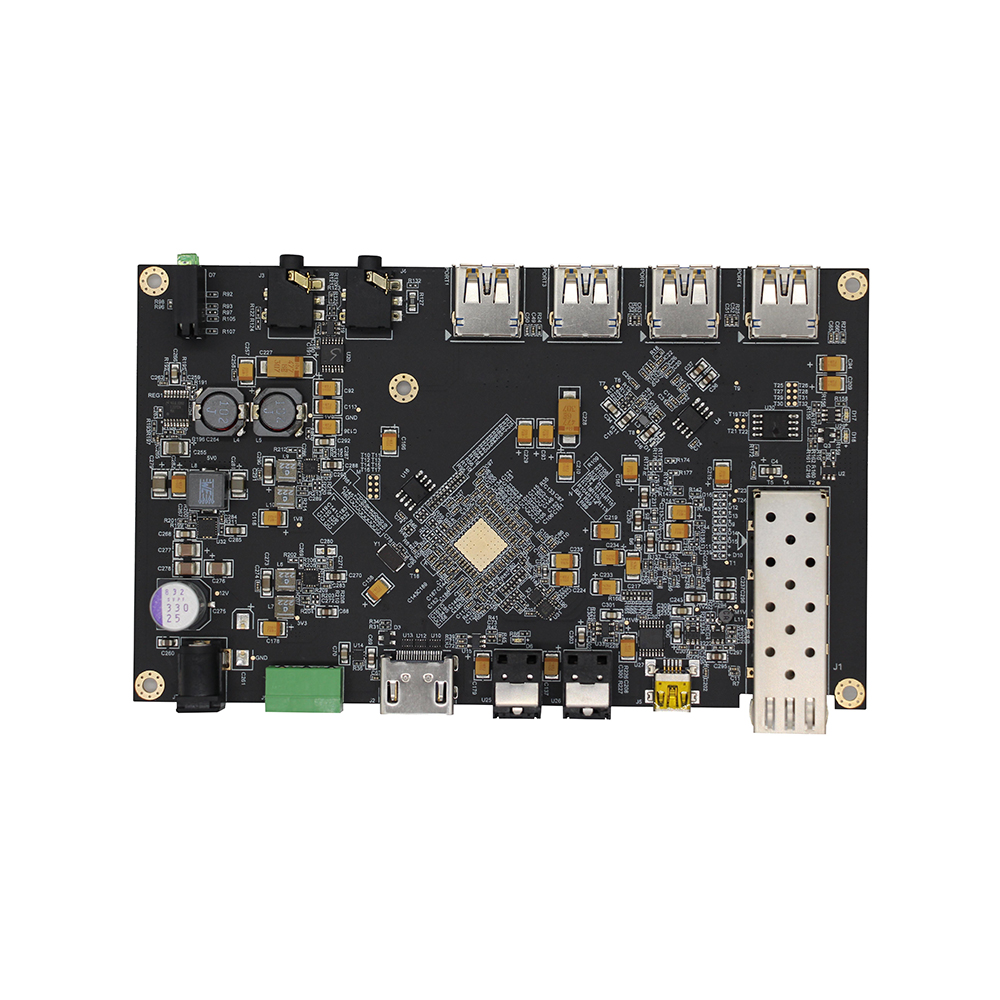

In today's fast-paced world, the demand for technology is constantly growing, and with it, the demand for fast and efficient PCB (Printed Circuit Board) assembly. As more and more industries turn to electronics for their operations, the need for cutting-edge, high-quality PCBs has never been greater. This growing demand has sparked the rise of fast PCB assembly factories, such as the one operated by {}.

{} is a leading company in the electronics manufacturing industry, with a strong reputation for producing high-quality PCBs for a wide range of applications. The company has recently amped up its production capabilities with the introduction of a state-of-the-art, fast PCB assembly factory. This new facility is equipped with the latest in manufacturing technology, allowing {} to significantly reduce production times while maintaining the highest standards of quality and precision.

The demand for fast PCB assembly has been driven in large part by the ever-evolving nature of technology. As the electronics industry continues to innovate and push the boundaries of what is possible, the need for faster turnaround times on PCB assembly has become a top priority for manufacturers. With the advent of technologies such as 5G, IoT, and AI, the demand for high-performance PCBs is only set to increase in the coming years, making fast PCB assembly an essential part of the manufacturing process.

One of the key benefits of fast PCB assembly is the ability to quickly bring new products to market. In today's competitive landscape, being able to rapidly prototype and iterate on new designs is crucial for staying ahead of the curve. Fast PCB assembly factories like the one operated by {} enable companies to quickly turn their ideas into reality, giving them a significant advantage in the marketplace.

Another important factor driving the demand for fast PCB assembly is the need for agility in manufacturing. With the global supply chain facing increasing challenges, manufacturers need to be able to adapt quickly to changing market conditions. By being able to rapidly produce high-quality PCBs, companies are able to respond to changes in demand more effectively, ultimately leading to increased profitability and customer satisfaction.

In addition to the benefits for manufacturers, fast PCB assembly also holds significant advantages for the end consumer. By being able to bring products to market more quickly, companies are able to deliver the latest technology to consumers faster than ever before. This not only gives consumers access to cutting-edge products sooner, but also allows companies to stay ahead of their competition and drive innovation in the industry.

As the demand for fast PCB assembly continues to grow, companies like {} are at the forefront of this revolution. With their advanced manufacturing capabilities and commitment to quality, {} is well-positioned to meet the needs of the electronics industry in the years to come. By investing in fast PCB assembly, companies are able to stay ahead of the curve and deliver the high-quality products that consumers demand.

In conclusion, the rise of fast PCB assembly factories is set to transform the electronics manufacturing industry. With the increasing demand for high-performance PCBs and the need for agility in manufacturing, fast PCB assembly is becoming a crucial part of the production process. Companies like {} are leading the way in this exciting new era of electronics manufacturing, shaping the future of technology and innovation.

Company News & Blog

LED Lights PCB Assembly in China - Manufacturing and Assembly Services

China LED Lights PCB Assembly: Revolutionizing the Lighting IndustryIn today's fast-paced technological advances, the demand for efficient and environmentally friendly lighting solutions has been on the rise. LED lighting has emerged as a popular and energy-efficient alternative to traditional incandescent and fluorescent lighting. As a result, the LED lights industry has been growing at a rapid pace, and China has been at the forefront of this revolution.With a commitment to innovation and sustainability, China-based LED lights PCB assembly company has been playing a crucial role in driving the growth of the LED lighting industry. With its cutting-edge technology and state-of-the-art manufacturing facilities, the company has established itself as a leading player in the global LED lights market.The company's core focus is on providing high-quality LED lights PCB assembly services to meet the growing demand for energy-efficient lighting solutions. With a strong emphasis on research and development, the company has been able to develop innovative and cost-effective PCB assembly solutions that are tailored to meet the specific requirements of its customers.One of the key factors that sets the company apart from its competitors is its commitment to sustainability. With a focus on reducing energy consumption and minimizing environmental impact, the company's LED lights PCB assembly services have been designed to meet the highest environmental standards. By utilizing advanced manufacturing processes and materials, the company has been able to produce LED lights that are not only energy-efficient but also durable and long-lasting.Furthermore, the company's strong commitment to quality and reliability has made it a trusted partner for a wide range of customers, including leading lighting manufacturers and suppliers. With a focus on continuous improvement and innovation, the company has been able to deliver high-quality LED lights PCB assembly services that are in line with the latest industry standards.In addition to its commitment to sustainability and quality, the company also prides itself on its efficient and reliable manufacturing processes. With a strong emphasis on precision and accuracy, the company's PCB assembly services are known for their high level of reliability and consistency. This has made the company a preferred choice for customers who require fast and dependable LED lights PCB assembly solutions.Moreover, the company's dedication to customer satisfaction has been another contributing factor to its success. By working closely with its customers, the company has been able to understand their specific needs and provide customized LED lights PCB assembly services that meet their requirements. This customer-centric approach has helped the company build long-term partnerships with its clients and establish a strong reputation in the LED lights industry.Looking ahead, China-based LED lights PCB assembly company is well-positioned to further drive innovation and growth in the LED lighting industry. With a focus on sustainable manufacturing practices, cutting-edge technology, and customer satisfaction, the company is poised to be a key player in shaping the future of LED lighting.In conclusion, China's LED lights PCB assembly company has been at the forefront of revolutionizing the lighting industry with its innovative and sustainable LED lights solutions. With a strong commitment to quality, reliability, and customer satisfaction, the company has established itself as a leading player in the global LED lights market. As the demand for energy-efficient lighting solutions continues to grow, the company is well-positioned to drive further innovation and growth in the LED lighting industry.

Efficient Production Process and Diverse Selection: Explore the Multilayer Board Factory

Title: Multilayer Board Factory Boosting Production Capacity in Response to Growing DemandIntroduction: [Company name], a prominent manufacturer of high-quality multilayer boards, is set to expand its production capacity to meet the ever-increasing demand in the market. With an impressive track record of delivering innovative and durable solutions for various industries, the company's decision to invest in expansion highlights its commitment to ensuring uninterrupted supply and enhancing customer satisfaction.(Paragraph 1)In light of recent market trends, substantial growth has been observed in the construction and electrical sectors, leading to rising demand for multilayer boards. This surge in demand necessitates the need for manufacturers such as [Company name] to upscale production capabilities. Recognizing this opportunity, the company has taken strategic measures to expand its manufacturing facilities, ensuring increased production and superior quality products to cater to evolving customer needs.(Paragraph 2)To support the expansion plans, [Company name] has invested a significant amount in state-of-the-art machinery, cutting-edge technology, and skilled manpower. The upgraded production infrastructure is designed to optimize efficiency, reduce production time, and ensure strict adherence to international quality standards. This investment will not only allow the company to meet the growing market demand but also maintain its position as an industry leader in manufacturing multilayer boards.(Paragraph 3)Moreover, the increased production capacity will enable [Company name] to provide timely and efficient solutions to its customers. The company's commitment to on-time delivery and customer satisfaction has played a vital role in establishing strong and lasting relationships with clients in various sectors, including construction, electrical, and telecommunications. The expanded facilities will further enhance the company's ability to fulfill large-scale orders while maintaining its trademark quality.(Paragraph 4)In addition to its focus on production capacity, [Company name] places utmost emphasis on sustainable manufacturing practices. The company implements eco-friendly processes and materials, ensuring minimal impact on the environment. By investing in energy-efficient machinery and optimizing resource utilization, [Company name] contributes to the industry's broader sustainability goals, attracting environmentally-conscious customers who prioritize sustainable practices.(Paragraph 5)By expanding its production capacity, [Company name] aims to reinforce its market position and cater to emerging opportunities both domestically and internationally. The company's dedication to continuous improvement, product innovation, and customer satisfaction has established its reputation as a reliable manufacturer in the multilayer board industry.(Paragraph 6)As the demand for multilayer boards continues to grow, the expanded production facilities of [Company name] will play a crucial role in meeting customer expectations. Whether it's for commercial or residential purposes, the enhanced production capabilities will enable the company to provide high-quality multilayer boards that fulfill industry requirements, while ensuring reliability, durability, and value for money.(Paragraph 7)In conclusion, [Company name]'s decision to invest and expand its production capacity reflects its commitment to meeting the escalating demand for multilayer boards. With state-of-the-art facilities, cutting-edge technology, and sustainable practices, the company aims to deliver innovative and durable solutions to various industries. By offering enhanced production capabilities, [Company name] strives to maintain its market leadership and continue providing excellent service to its valued customers.

How recent news updates are impacting the SEO landscape

Title: Semiconductors Power the Future: A glance into the world of advanced chip manufacturingIntroduction:Semiconductors, the building blocks of modern electronics, play an integral role in driving technological advancements across various industries, including communication, computing, automotive, and healthcare. One prominent player in the semiconductor industry, referred to here as "Chip," has emerged as a frontrunner in the race to develop and manufacture advanced chips. With a deep understanding of the market's needs, Chip has successfully positioned itself as a leading provider of cutting-edge semiconductor solutions. In this article, we will delve into Chip's remarkable journey, exploring their commitment to innovation, sustainable manufacturing practices, and the crucial role they play in shaping the future.Part 1: Pioneering Innovation:Chip, a global leader in semiconductor manufacturing, continuously strives to innovate and push the boundaries of what is possible with chip technology. The company's R&D teams work relentlessly to develop groundbreaking products, focusing on improving efficiency, computational power, and integration capabilities. By investing heavily in research and development, Chip sets itself apart from competitors, ensuring its position at the forefront of advanced technology.Part 2: Revolutionizing Computing:In today's digital era, the demand for high-performance computing solutions has skyrocketed. Chip's cutting-edge processors have revolutionized the computing industry, enabling faster data processing, seamless multitasking, and enhanced user experiences. Leveraging their expertise in chip design, Chip has successfully delivered powerful processors, catering to the needs of modern consumers, enterprises, and data centers.Part 3: Empowering Connectivity:With the advent of 5G technology, the need for reliable and high-speed connectivity has become paramount. Chip recognizes this growing demand and has dedicated substantial resources to develop advanced chipsets that power next-generation networks. By combining their expertise in chip design and wireless connectivity, Chip enables faster and more efficient communication, empowering individuals and businesses to stay seamlessly connected.Part 4: Automotive Advancements:The automotive industry is undergoing a digital transformation, with autonomous driving and smart vehicles becoming increasingly prevalent. Chip's semiconductor solutions have played a significant role in this transformation, providing the necessary hardware and processing power to support advanced driver-assistance systems (ADAS) and in-car infotainment systems. Chip's commitment to innovation in this field ensures safer, smarter, and more connected vehicles on our roads.Part 5: A Sustainable Future:In addition to innovation, Chip recognizes the importance of sustainable manufacturing practices. As part of their corporate social responsibility, the company actively works towards reducing its environmental footprint by implementing energy-efficient production processes and recycling initiatives. These efforts not only help preserve the planet but also position Chip as an industry leader when it comes to sustainability in semiconductor manufacturing.Conclusion:Chip's dedication to pushing the boundaries of chip technology and commitment to sustainability make it a formidable player in the global semiconductor industry. Through groundbreaking innovation, they continue to shape the future of computing, connectivity, and automotive advancements. As the demand for advanced semiconductors grows, Chip is poised to meet these challenges head-on, ensuring that their products power the devices and technologies that will shape our world for years to come.

Quality Circuit Board: A Closer Look at High-Quality Options

High-Quality Circuit Board For (need remove brand name) Offers Superior Performance and ReliabilityWith the ever-increasing demand for advanced electronic devices and technology, the need for high-quality circuit boards has become more crucial than ever. (Brand name) is a leading manufacturer of high-quality circuit boards that are known for their exceptional performance and reliability. Their commitment to innovation and excellence has made them a trusted name in the industry.The circuit boards produced by (Brand name) are designed to meet the needs of a wide range of applications, including industrial, automotive, aerospace, and consumer electronics. Whether it's a complex multi-layered PCB or a simple single-layer board, (Brand name) prides itself on delivering top-notch quality and performance for all their products.One of the key factors that set (Brand name) apart from their competitors is their state-of-the-art manufacturing facility. The company invests heavily in cutting-edge technology and equipment to ensure that their circuit boards are of the highest quality. With a team of highly skilled engineers and technicians, (Brand name) is able to produce circuit boards that meet the most stringent quality standards.In addition to their dedication to quality, (Brand name) is also committed to providing exceptional customer service. The company works closely with their clients to understand their specific requirements and to develop customized solutions to meet their needs. Whether it's a prototype for a new product or a large-scale production run, (Brand name) has the experience and expertise to deliver on time and on budget.Moreover, (Brand name) understands the importance of environmental sustainability and is committed to reducing their carbon footprint. The company has implemented eco-friendly manufacturing practices and uses recyclable materials whenever possible. This commitment to sustainability has not only earned them the trust of their customers but has also positioned them as a responsible corporate citizen.One of the most popular products offered by (Brand name) is their high-speed and high-frequency circuit boards. These specialized boards are designed to handle the demands of high-speed data transmission and are used in a wide range of applications, including telecommunications, networking, and computing. The superior performance and reliability of these boards have made them the top choice for clients who require the best in electronic components.In addition to high-speed and high-frequency boards, (Brand name) also offers a range of other circuit board products, including rigid, flex, and rigid-flex boards. Each of these products is designed and manufactured with the same level of precision and attention to detail, ensuring that they meet the exact specifications of their clients.As technology continues to advance at a rapid pace, the demand for high-quality circuit boards will only continue to grow. (Brand name) is well-positioned to meet this demand and to continue setting the standard for excellence in the industry. With their unwavering commitment to quality, innovation, and customer service, (Brand name) is poised to remain a leader in the manufacturing of high-quality circuit boards for years to come.In conclusion, (Brand name) is a company that prides itself on delivering superior performance and reliability in the production of high-quality circuit boards. With a state-of-the-art manufacturing facility, a team of skilled professionals, and a commitment to customer service and sustainability, (Brand name) is a trusted name in the industry. Whether it's for high-speed data transmission, telecommunications, or any other application, customers can rely on (Brand name) to deliver the best in electronic components.

Revolutionary 3D Printed Circuit Boards Taking the Electronics Industry by Storm

[Company Name] Revolutionizes the Manufacturing Industry with 3D Printed Circuit Boards[City, Date] - In a ground-breaking move that is set to transform the manufacturing industry, [Company Name], a leading technology solutions provider, has unveiled its latest innovation: 3D printed circuit boards. This cutting-edge technology combines the benefits of additive manufacturing with the production of high-quality electronic components, marking a major milestone in the evolution of PCB manufacturing.Traditionally, the production of circuit boards involved complex and time-consuming processes such as etching copper patterns on substrates, drilling holes, and soldering components. However, [Company Name] has completely revolutionized this process by introducing 3D printing techniques to produce circuit boards. This new approach eliminates the need for multiple layers and expensive equipment, making circuit board production faster, more cost-effective, and highly customizable.The integration of 3D printing technology into circuit board manufacturing opens up a world of possibilities. By layering conductive ink onto a substrate, [Company Name] is able to create intricate circuitry with high precision and accuracy. This process has significant advantages, including reduced production time, improved efficiency, and enhanced flexibility in design modifications.Moreover, the use of 3D printing technology allows for the integration of multiple components into a single circuit board, eliminating the need for complex wiring and reducing the overall size of the electronic device. This breakthrough technology has the potential to revolutionize industries such as consumer electronics, automotive, aerospace, and healthcare, where miniaturization and efficiency are paramount.[Company Name] has always been at the forefront of innovation, and the development of 3D printed circuit boards is a testament to their commitment to revolutionizing the manufacturing industry. By harnessing the power of additive manufacturing, the company is able to significantly reduce production costs while maintaining the highest standard of quality and reliability.To ensure that the 3D printed circuit boards meet the rigorous standards expected in the electronics industry, [Company Name] has invested heavily in research and development. The company has established state-of-the-art testing facilities and partnered with industry experts to validate the performance and durability of their 3D printed circuit boards.Not only does this breakthrough technology enhance the efficiency and performance of electronic devices, but it also has a positive environmental impact. Traditional circuit board manufacturing processes generate significant waste, including chemical byproducts and non-recyclable materials. However, by adopting 3D printing techniques, [Company Name] reduces waste, lowers energy consumption, and contributes to a more sustainable manufacturing process.[Company Name]'s 3D printed circuit boards have already gained significant attention from major players in the industry. Several leading electronics manufacturers have expressed interest in adopting this technology to improve their product performance and streamline their manufacturing processes.The introduction of 3D printed circuit boards by [Company Name] is set to disrupt the manufacturing industry and set new standards for quality, efficiency, and sustainability. With this breakthrough technology, the company reaffirms its position as a pioneer in the field of advanced manufacturing solutions.As 3D printing continues to evolve and gain widespread adoption, [Company Name] remains committed to pushing the boundaries of innovation. Their dedication to providing cutting-edge technological solutions is transforming industries and revolutionizing the way products are designed, manufactured, and consumed.About [Company Name]:[Company Name] is a leading technology solutions provider specializing in advanced manufacturing techniques and innovative solutions. With a strong focus on research and development, the company aims to revolutionize industries through the integration of cutting-edge technologies. By offering customized solutions and impeccable quality, [Company Name] has established itself as a trusted partner for businesses seeking to stay ahead in the rapidly evolving technological landscape.

Latest IPC-6012 Standard Updates: What You Need to Know

IPC-6012 is a set of standards for the design and manufacture of printed circuit boards (PCBs). These standards are set by the IPC (Association Connecting Electronics Industries) and are used to ensure that PCBs meet the necessary requirements for quality and reliability.Company Introduction:{Company Name} is a leading manufacturer of electronic components and PCBs. With over 20 years of experience in the industry, {Company Name} has built a reputation for delivering high-quality products and reliable service to its customers. The company is dedicated to staying up to date with the latest technologies and industry standards, and as such, it is committed to maintaining compliance with IPC-6012 standards.News Content:In the world of electronics manufacturing, the quality and reliability of printed circuit boards (PCBs) are paramount. Manufacturers and assemblers rely on industry standards to ensure that their products meet the necessary criteria for performance and safety. One such standard is IPC-6012, which specifies the requirements for the design and manufacture of PCBs.{Company Name}, a leading manufacturer of electronic components and PCBs, is proud to announce its continued compliance with IPC-6012 standards. The company has long been committed to delivering high-quality products to its customers, and its adherence to industry standards is a testament to this dedication.IPC-6012 covers a wide range of requirements for PCBs, including materials, design, fabrication, and testing. By following these standards, manufacturers can ensure that their PCBs meet the necessary criteria for performance, reliability, and safety. {Company Name} recognizes the importance of these standards and is dedicated to upholding them in its manufacturing processes.By complying with IPC-6012 standards, {Company Name} demonstrates its commitment to delivering reliable and high-quality PCBs to its customers. The company understands the significance of these standards in the electronics industry and is proud to meet and exceed them in its manufacturing practices.{Company Name} has built a strong reputation for delivering top-notch electronic components and PCBs to its customers. Its compliance with IPC-6012 standards further solidifies its position as a trusted and reliable manufacturing partner in the industry. Customers can have confidence in the quality and reliability of {Company Name}'s products, knowing that they meet the necessary industry standards.In conclusion, IPC-6012 is an essential standard for the design and manufacture of printed circuit boards, and {Company Name} is proud to announce its continued compliance with these standards. By upholding these requirements, the company ensures that its products meet the necessary criteria for performance, reliability, and safety. Customers can trust {Company Name} to deliver high-quality electronic components and PCBs that meet the industry's stringent standards.

Top Flex PCB Design Suppliers for OEM Manufacturing

OEM Flex PCB Design Suppliers Combine with Leading Company to Offer Cutting-Edge SolutionsIn today's fast-paced technological world, the demand for high-quality and innovative PCB design solutions is at an all-time high. As a leading company in the industry, the collaboration with OEM Flex PCB Design Suppliers () is set to bring cutting-edge solutions to the market.With decades of experience in the industry, OEM Flex PCB Design Suppliers has established itself as a trusted and reliable partner for companies looking to create cutting-edge products. Their expertise in flex PCB design and manufacturing has made them a go-to choice for businesses across various industries, from consumer electronics to automotive and aerospace.By combining their expertise with the company’s () leading position in the market, the collaboration is expected to offer a comprehensive range of flexible PCB design solutions to meet the evolving needs of customers. This partnership will leverage the strengths of both companies, allowing them to deliver high-quality, cost-effective, and reliable solutions to their clients.Flex PCBs, or flexible printed circuit boards, are becoming increasingly popular in the industry due to their ability to conform to a variety of shapes and sizes, making them ideal for applications where space is limited. With the demand for flexible PCBs on the rise, the partnership between OEM Flex PCB Design Suppliers and the company is well-positioned to meet the needs of customers looking for cutting-edge solutions in this space.One of the key benefits of this collaboration is the ability to offer a complete range of flex PCB design services, from initial concept and design to prototyping and mass production. This end-to-end approach will ensure that customers receive the highest level of service and support throughout the entire product development process.Additionally, the combined expertise of both companies will enable them to stay ahead of the curve when it comes to technological advancements and industry trends. This means that customers can expect to receive the latest innovations and advancements in flex PCB design, helping them to stay competitive in their respective markets.Furthermore, the partnership will also allow for greater efficiency and cost savings, as the companies can leverage their combined resources and expertise to streamline the design and manufacturing process. This will result in faster turnaround times and lower production costs, ultimately benefiting customers in terms of both time and money.As a leading company in the industry, has a strong reputation for delivering high-quality and reliable solutions to its customers. This partnership with OEM Flex PCB Design Suppliers is a testament to their commitment to offering the best possible solutions to their clients, while also staying at the forefront of technological advancements in flex PCB design.In conclusion, the collaboration between OEM Flex PCB Design Suppliers and the company is a significant development in the industry. By combining their expertise and resources, the companies are well-positioned to offer cutting-edge flex PCB design solutions to meet the evolving needs of customers across various industries. This partnership is not only a win-win for both companies, but also for customers looking for high-quality, innovative, and cost-effective flex PCB design services.

Leading Manufacturer of High-Quality Double Layer PCBs: A Game-Changer in Electronics Industry

Title: Industry-Leading Double Layer PCB Manufacturer Revitalizes Electronics MarketIntroduction:In an ever-evolving electronics industry, the demand for high-quality and reliable electronic components continues to grow. Stepping up to meet this demand, a renowned double layer PCB manufacturer has successfully established itself as an industry leader. With a strong commitment to innovation, technological expertise, and customer satisfaction, this company has emerged as a powerful player in the global electronics market. Let's delve into their story and explore how they are revolutionizing the landscape.I. Product Excellence:With an unwavering dedication to product excellence, this double layer PCB manufacturer consistently crafts superior quality printed circuit boards (PCBs). By adhering to meticulous quality control procedures and utilizing cutting-edge manufacturing techniques, they ensure the highest level of durability and efficiency in every PCB they produce. Their products have gained recognition from customers across various industries, reaffirming the brand's reputation as a reliable and trusted supplier.II. State-of-the-Art Facilities:The success of this manufacturer can be attributed to its state-of-the-art facilities, equipped with advanced machinery and technology. These facilities are fully compliant with international standards, allowing the company to cater to a diverse range of clients on a global scale. From circuit design to assembly, their streamlined production process ensures efficient manufacturing and quick turnaround times without compromising on quality.III. Technological Expertise:At the core of this company's success lies its exceptional technological expertise. With a highly skilled team of engineers and technicians, they have mastered the intricacies of double layer PCB manufacturing. Their expertise enables them to design and produce PCBs that meet the specific needs of various industries, including telecommunications, automotive, aerospace, and consumer electronics. By staying at the forefront of technological advancements, this manufacturer consistently delivers innovative solutions for even the most demanding applications.IV. Customer-Centric Approach:Understanding the importance of customer satisfaction, this double layer PCB manufacturer places customers at the heart of their operations. By offering personalized solutions, prompt technical support, and competitive pricing, they foster long-term partnerships with their clients. Moreover, their commitment to open communication and transparent business practices ensures that clients are actively involved throughout the manufacturing process. This level of dedication to customer-centricity distinguishes them from their competitors and solidifies their position as a preferred PCB supplier.V. Focus on Sustainability:In today's environmentally conscious market, this manufacturer recognizes the significance of sustainability. They prioritize eco-friendly practices across their operations, from sourcing materials to waste management. By minimizing their carbon footprint and adhering to various industry regulations, they contribute to a greener electronics market. This commitment to sustainable manufacturing not only benefits the environment but also resonates with customers who value socially responsible businesses.VI. Future Expansion and Innovation:As the electronics industry continues to evolve, this double layer PCB manufacturer remains committed to continuous growth and innovation. They invest heavily in research and development to explore emerging technologies and stay ahead of industry trends. By anticipating the needs of their customers, they aim to provide cutting-edge solutions that address challenges and open up new possibilities in the electronics market.Conclusion:Through their unwavering commitment to product excellence, technological expertise, customer-centric approach, sustainability, and continuous innovation, this esteemed double layer PCB manufacturer has witnessed remarkable success in the electronics industry. Their state-of-the-art facilities, highly skilled workforce, and dedication to quality have cemented their position as a go-to supplier for businesses worldwide. As they continue to broaden their horizons and pioneer advancements in the field, this manufacturer will undoubtedly play a crucial role in driving the electronics market forward.

Discover the Latest Updates on Electronic PCBA Factories

Electronic PCB Assembly Factories: Revolutionizing the Electronics IndustryIn today's rapidly evolving technological landscape, the demand for high-quality electronic devices is surging. From smartphones to smart home appliances, electronic gadgets have become an integral part of our everyday lives. To meet this ever-increasing demand, electronic PCBA factories have emerged as key players, revolutionizing the electronics industry.[Company Introduction]One such leading company in this domain is {}, a pioneer in electronic PCB assembly. With extensive experience and expertise, {} has been at the forefront of meeting the diverse needs of customers worldwide. Their commitment to quality, innovation, and customer satisfaction has set them apart from the rest.With a state-of-the-art manufacturing facility equipped with advanced machinery and cutting-edge technology, {} offers a wide range of services, including PCB design, component sourcing, PCB assembly, testing, and final product assembly. Their highly skilled workforce ensures efficient production, meticulous quality control, and timely delivery, making them a trusted partner for businesses seeking electronic PCBA solutions.By harnessing the latest Industry 4.0 trends, {} has embraced automation and digitalization, enabling them to produce high-quality electronic products with utmost precision and efficiency. This not only reduces production costs but also greatly enhances the overall productivity and competitiveness of their offerings.One of the distinct advantages of partnering with {} is their comprehensive PCB design service. With an experienced team of design engineers, they guide their clients right from the conceptualization stage, considering factors such as material selection, design manufacturability, cost optimization, and performance criteria. This holistic approach ensures that each design is optimized for efficiency and reliability, meeting the specific requirements of the end product.Component sourcing is another critical aspect of the electronic PCBA process, and {} excels in this realm as well. They have established strong partnerships with renowned component manufacturers worldwide, ensuring a steady supply of high-quality components while keeping costs in check. This strategic procurement approach enables them to offer competitive pricing and shorter lead times, saving their customers valuable time and resources.Once the PCB design and component sourcing stages are complete, {} takes over the PCB assembly process. Harnessing their advanced equipment, they meticulously solder the components onto the PCB, ensuring precise placement and soldering techniques to guarantee the long-term reliability of the final product. Their commitment to quality is evident in every step of the assembly process, with rigorous inspection and testing procedures carried out to identify any defects or issues before delivery.The effectiveness and reliability of the electronic products are thoroughly tested at {}'s testing facility. They meticulously evaluate the functionality, performance, and durability of the assembled PCBs, leaving no room for errors. With comprehensive testing procedures in place, all products leaving their manufacturing facility are of the highest quality, meeting international standards and certifications.As an added advantage, {} also provides final product assembly services, where they integrate the assembled PCB with other components, casings, and peripherals, providing a complete, ready-to-use product. This end-to-end manufacturing approach allows their clients to focus on product development and marketing, while {} takes care of the manufacturing process, ensuring a seamless experience.In conclusion, electronic PCBA factories like {}, with their expertise, advanced technology, and commitment to quality, are revolutionizing the electronics industry. Their comprehensive range of services, from PCB design to final product assembly, ensures an efficient and streamlined manufacturing process, meeting the growing demand for electronic devices worldwide. With continued innovation and adaptation to emerging technologies, {} is well-positioned to remain a leader in the industry and a preferred partner for businesses seeking electronic PCB assembly solutions.

High-Quality PCB Assembly Factory in China Leading the Industry

China's LED PCB assembly factory, located in the heart of the nation's bustling manufacturing sector, is making waves in the industry with its high-quality production and innovative technology. With a commitment to excellence and a focus on customer satisfaction, the factory has quickly become a leader in the LED industry and a preferred supplier for both domestic and international clients.As a leading LED PCB assembly factory in China, the company is proud to offer a comprehensive range of services, including PCB design, assembly, and testing. With a state-of-the-art facility and a team of highly skilled engineers and technicians, the factory is able to provide clients with a wide range of custom LED PCB solutions to meet their specific needs and requirements. From small-scale prototypes to large-scale production runs, the factory has the capability to handle projects of all sizes and complexities.In addition to its cutting-edge production capabilities, the LED PCB assembly factory is also dedicated to providing exceptional customer service and support. The company's team of experts works closely with clients to understand their unique needs and to develop customized solutions that meet their exact specifications. With a strong emphasis on communication and collaboration, the factory is able to ensure that every project is completed on time and within budget, while maintaining the highest standards of quality and reliability.At the heart of the LED PCB assembly factory's success is its commitment to innovation and technological advancement. The company is constantly investing in the latest equipment and technology to ensure that it remains at the forefront of the industry, offering clients access to the most advanced LED PCB solutions available. Whether it's implementing new manufacturing processes, refining existing production techniques, or investing in new research and development initiatives, the factory is committed to pushing the boundaries of what is possible in LED PCB assembly.In addition to its focus on innovation, the LED PCB assembly factory is also dedicated to sustainability and environmental responsibility. The company is committed to minimizing its environmental impact through the use of energy-efficient production processes, waste reduction initiatives, and the implementation of eco-friendly materials and practices. By prioritizing sustainability, the factory is able to not only reduce its own carbon footprint but also offer clients the option to choose environmentally friendly LED PCB solutions.Furthermore, the LED PCB assembly factory places a strong emphasis on quality control and reliability. The company's rigorous quality assurance processes ensure that every PCB produced meets the highest standards of reliability and performance. From initial design and prototyping to final assembly and testing, the factory's team of experts meticulously inspects every component to ensure that it meets the strictest quality standards.In addition to its commitment to quality, innovation, and sustainability, the LED PCB assembly factory is also dedicated to fostering a culture of continuous improvement and learning. The company encourages its employees to pursue ongoing training and development opportunities to further enhance their skills and knowledge, ensuring that they remain at the cutting edge of the industry.With its unwavering commitment to excellence, innovation, and customer satisfaction, China's LED PCB assembly factory continues to set the standard for LED PCB production in the industry. As the factory continues to grow and expand its capabilities, it is poised to remain a leader in the LED PCB assembly industry for years to come.