High-Quality Circuit Board Factory: The Latest Developments and Trends

By:Admin

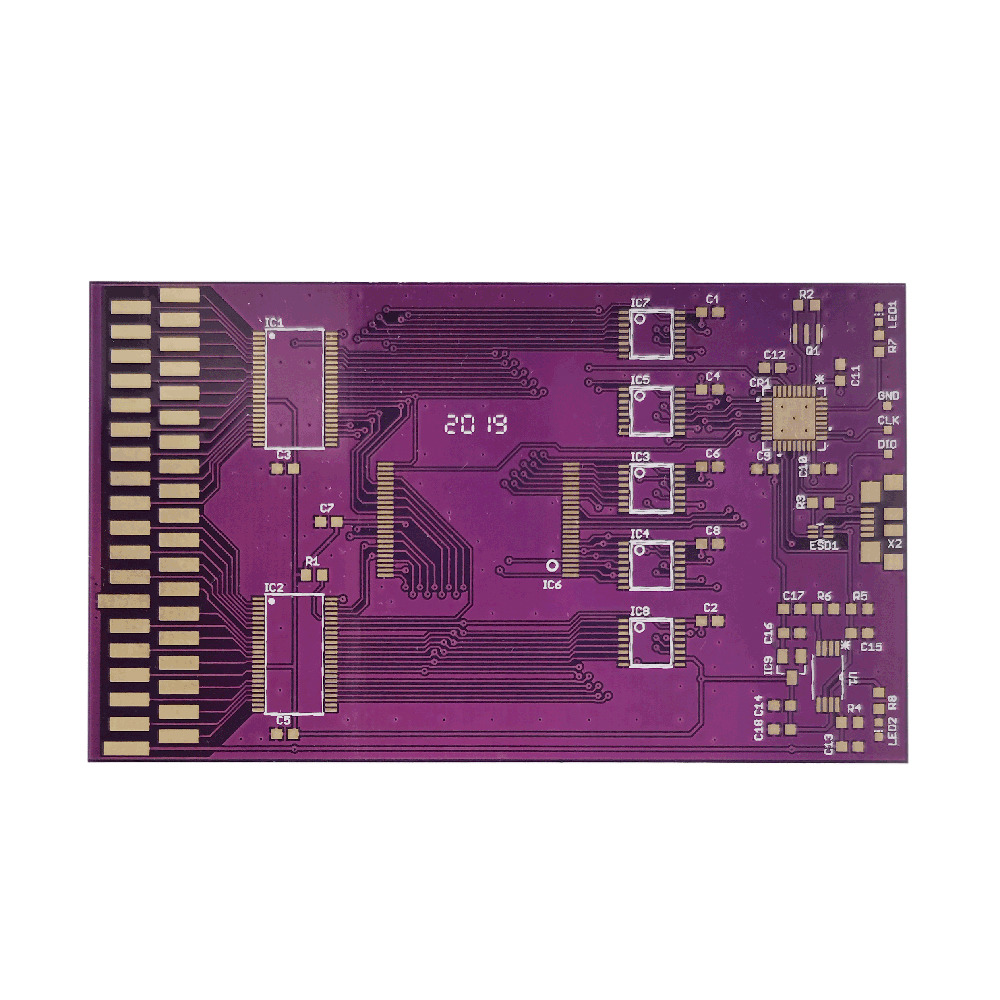

Founded in 1995, Circuit Board Factory has established itself as a reputable and reliable supplier of circuit boards for a wide range of applications. The company prides itself on their commitment to quality, innovation, and customer satisfaction. With a strong emphasis on research and development, Circuit Board Factory has been able to stay ahead of the curve in a rapidly evolving industry.

The recent expansion of their production capacity comes in the wake of a growing market demand for advanced circuit boards with high-speed and high-density capabilities. To address this demand, Circuit Board Factory has made strategic investments in new machinery and equipment that will enable them to produce cutting-edge circuit boards with greater efficiency and precision. This will allow the company to offer their customers the latest technological advancements in circuit board design and manufacturing.

In addition to the technological investments, Circuit Board Factory has also expanded their physical production facility to accommodate the increased manufacturing capacity. This will enable the company to streamline their production processes and improve overall operational efficiency. By optimizing their production facility, Circuit Board Factory aims to reduce lead times and enhance their ability to meet tight production deadlines.

Furthermore, Circuit Board Factory has also ramped up their personnel training and development efforts to ensure that their workforce is equipped with the necessary skills and knowledge to operate the new equipment and technology effectively. The company recognizes that their employees are their most valuable asset and is committed to providing them with ongoing training and professional development opportunities.

The decision to expand the production capacity reflects Circuit Board Factory's dedication to staying ahead of industry trends and meeting the evolving needs of their customers. By investing in new technology, equipment, and personnel, the company is positioning itself to maintain its competitive edge in the market and continue to be a trusted partner for businesses seeking high-quality circuit boards.

With the expanded production capacity, Circuit Board Factory is poised to take on new opportunities and partnerships in the electronics industry. The company is actively seeking to collaborate with businesses in emerging sectors such as renewable energy, electric vehicles, and IoT devices, where the demand for advanced circuit boards is expected to grow significantly in the coming years.

In conclusion, Circuit Board Factory's expansion of its production capacity represents a significant milestone in the company's growth trajectory. By leveraging new technology and equipment, the company is well-positioned to meet the increasing demand for high-quality circuit boards and continue to push the boundaries of innovation in the electronics industry. As Circuit Board Factory looks towards the future, it remains committed to its core values of quality, innovation, and customer satisfaction, and is poised for continued success in the years to come.

Company News & Blog

Discover the top-tier PCBA Factory for High-Quality Electronic Manufacturing Services

[Your Company Name] Set to Revolutionize PCB Manufacturing with its State-of-the-Art Factory[Location], [Date] - [Your Company Name], a leading player in the electronics manufacturing industry, is all set to reshape the way printed circuit board assemblies (PCBAs) are manufactured with the unveiling of its cutting-edge factory. Equipped with the latest technology and powered by a team of highly skilled professionals, the new facility promises to deliver superior quality PCBAs while increasing production efficiency and reducing lead times.The new factory, strategically located in [Location], is the culmination of years of research and development. [Your Company Name] has always been at the forefront of innovation, and this state-of-the-art facility is a testament to its commitment to excellence. The factory boasts a spacious layout, optimized production lines, and a controlled manufacturing environment to ensure the highest standards of quality are maintained throughout the manufacturing process.One of the key features that sets [Your Company Name]'s factory apart is its cutting-edge PCB fabrication capabilities. Utilizing advanced equipment and techniques, the factory is capable of producing high-quality, precision-engineered PCBs. This not only enhances the overall performance of the end products but also provides increased reliability, particularly in demanding applications such as aerospace and defense.Furthermore, the factory's surface mount technology (SMT) lines have been designed to handle even the most complex and densely populated PCB assemblies. With state-of-the-art pick-and-place machines, solder paste printers, and reflow ovens, the SMT lines ensure precise component placement, accurate soldering, and optimal thermal profiles, resulting in PCBAs of unparalleled quality.In addition to its advanced manufacturing capabilities, [Your Company Name]'s factory prioritizes environmental sustainability. The facility has implemented several eco-friendly practices, including waste management and energy-efficient systems. By adhering to strict environmental regulations, the company reiterates its commitment to minimizing its carbon footprint and contributing to a greener future."We are incredibly proud of our new factory," says [Spokesperson Name], [Your Company Name]'s spokesperson. "With this investment, we have solidified our position as an industry leader and paved the way for further growth and innovation. Our advanced manufacturing processes, coupled with our highly skilled workforce, enable us to deliver high-quality PCBAs to our clients faster than ever before."[Your Company Name], established in [Year], has built a strong reputation for delivering top-notch electronics manufacturing solutions. Whether it's prototyping, low-volume production, or full-scale manufacturing, the company has consistently exceeded client expectations. Its extensive experience across industries, including telecommunications, medical devices, industrial automation, and consumer electronics, positions [Your Company Name] as a trusted partner for both established companies and startups alike.As the demand for PCBAs continues to grow, [Your Company Name]'s new factory positions the company to meet the rising requirements of the market effectively. By combining cutting-edge technology, streamlined processes, and a customer-centric approach, [Your Company Name] is poised to revolutionize PCB manufacturing and set new industry standards.About [Your Company Name]:[Your Company Name] is a globally recognized provider of electronics manufacturing services, specializing in printed circuit board assemblies. With a commitment to excellence, the company offers a wide range of services, including PCB fabrication, component sourcing, PCB assembly, and testing. [Your Company Name] caters to various industries, including telecommunications, medical devices, industrial automation, and consumer electronics, providing end-to-end solutions from concept to production.

Discover the Latest Developments in Taiwanese PCB Manufacturing for China Market

Title: China-Taiwan PCB Manufacturers Witness Continuous Growth in the Ever-Evolving Electronics IndustryIntroduction (152 words):In the dynamic landscape of the global electronics industry, China-Taiwan PCB (Printed Circuit Board) manufacturers have emerged as major players, consistently pushing the boundaries of innovation and meeting the growing demands of diverse sectors. Renowned for their cutting-edge technology, reliable production capabilities, and comprehensive product lines, these manufacturers have garnered recognition both domestically and internationally. In this article, we will highlight the remarkable achievements of China-Taiwan PCB manufacturers, while examining their contribution to the electronics industry and exploring the factors driving their ongoing success. Furthermore, we will delve into the strategies employed by these companies to maintain their competitive edge amidst technological advancements and evolving market trends.I. Pioneers in Technological Advancements (173 words)China-Taiwan PCB manufacturers have positioned themselves at the forefront of technological advancements. By investing heavily in research and development activities, they continuously introduce innovative solutions that cater to the ever-changing requirements of the electronics industry. Their ability to manufacture PCBs with intricate designs, high-density interconnects, and advanced materials has not only facilitated the miniaturization of electronic devices but has also enhanced their functionality and performance.The integration of emerging technologies, such as 5G, Internet of Things (IoT), and Artificial Intelligence (AI), has opened new avenues for China-Taiwan PCB manufacturers. These companies have successfully adapted their production lines to produce PCBs compatible with these technologies, further cementing their position as industry leaders. By leveraging their expertise and resources, they have effectively optimized the design, manufacturing, and testing processes, ensuring high-quality products that meet the stringent standards and specifications demanded in the market.II. Meeting Diverse Industry Demands (161 words)China-Taiwan PCB manufacturers possess the versatility necessary to cater to a wide range of industry demands. With the steady growth of consumer electronics, automotive, aerospace, telecommunications, and medical sectors, these manufacturers have capitalized on market opportunities by offering tailored solutions to each industry's unique requirements.The ability to provide flexible PCBs and rigid-flex PCBs has been instrumental in accommodating the demand for compact and durable electronic products. Moreover, their extensive manufacturing capabilities enable them to produce single-sided, double-sided, and multilayer PCBs, with layers ranging from two to over sixty, catering to the varying complexity of electronic devices.Maintaining strong relationships with leading OEMs (Original Equipment Manufacturers) and embracing collaborative partnerships with technology giants further bolsters the position of China-Taiwan PCB manufacturers in the global market. By aligning their production capabilities with the specific requirements of these companies, they ensure seamless integration and reliable performance in the final products.III. Global Reach and Market Competitiveness (157 words)China-Taiwan PCB manufacturers have successfully expanded their footprint on a global scale, positioning themselves as key players in the international market. By adhering to stringent international standards and certifications, combined with the use of advanced manufacturing techniques, these manufacturers have earned the trust and confidence of customers worldwide.In addition to their technical prowess, China-Taiwan PCB manufacturers have embraced sustainability practices, promoting environmentally friendly manufacturing processes. This is reflected in their compliance with RoHS (Restriction of Hazardous Substances) directive, which restricts the use of certain hazardous substances in electrical and electronic equipment, leading to safer and greener products.Conclusion (157 words)The success of China-Taiwan PCB manufacturers can be attributed to their unwavering commitment to technological advancements, their ability to adapt to diverse industry demands, and their relentless pursuit of excellence. By continually pushing the boundaries of innovation, they have strengthened their foothold in the global electronics market and established themselves as industry leaders.Looking ahead, these manufacturers will need to stay abreast of technological developments, such as the rise of flexible and wearable electronics, to maintain their competitive edge. Furthermore, investment in talent development and strategic collaborations will be vital to sustain their growth trajectory and fulfill the ever-increasing demand for advanced PCB solutions.As the electronics industry evolves at an unprecedented pace, China-Taiwan PCB manufacturers are poised to continue shaping its trajectory with their commitment to excellence and ability to deliver cutting-edge technology.

Discover the Latest Updates on Electronic PCBA Factories

Electronic PCB Assembly Factories: Revolutionizing the Electronics IndustryIn today's rapidly evolving technological landscape, the demand for high-quality electronic devices is surging. From smartphones to smart home appliances, electronic gadgets have become an integral part of our everyday lives. To meet this ever-increasing demand, electronic PCBA factories have emerged as key players, revolutionizing the electronics industry.[Company Introduction]One such leading company in this domain is {}, a pioneer in electronic PCB assembly. With extensive experience and expertise, {} has been at the forefront of meeting the diverse needs of customers worldwide. Their commitment to quality, innovation, and customer satisfaction has set them apart from the rest.With a state-of-the-art manufacturing facility equipped with advanced machinery and cutting-edge technology, {} offers a wide range of services, including PCB design, component sourcing, PCB assembly, testing, and final product assembly. Their highly skilled workforce ensures efficient production, meticulous quality control, and timely delivery, making them a trusted partner for businesses seeking electronic PCBA solutions.By harnessing the latest Industry 4.0 trends, {} has embraced automation and digitalization, enabling them to produce high-quality electronic products with utmost precision and efficiency. This not only reduces production costs but also greatly enhances the overall productivity and competitiveness of their offerings.One of the distinct advantages of partnering with {} is their comprehensive PCB design service. With an experienced team of design engineers, they guide their clients right from the conceptualization stage, considering factors such as material selection, design manufacturability, cost optimization, and performance criteria. This holistic approach ensures that each design is optimized for efficiency and reliability, meeting the specific requirements of the end product.Component sourcing is another critical aspect of the electronic PCBA process, and {} excels in this realm as well. They have established strong partnerships with renowned component manufacturers worldwide, ensuring a steady supply of high-quality components while keeping costs in check. This strategic procurement approach enables them to offer competitive pricing and shorter lead times, saving their customers valuable time and resources.Once the PCB design and component sourcing stages are complete, {} takes over the PCB assembly process. Harnessing their advanced equipment, they meticulously solder the components onto the PCB, ensuring precise placement and soldering techniques to guarantee the long-term reliability of the final product. Their commitment to quality is evident in every step of the assembly process, with rigorous inspection and testing procedures carried out to identify any defects or issues before delivery.The effectiveness and reliability of the electronic products are thoroughly tested at {}'s testing facility. They meticulously evaluate the functionality, performance, and durability of the assembled PCBs, leaving no room for errors. With comprehensive testing procedures in place, all products leaving their manufacturing facility are of the highest quality, meeting international standards and certifications.As an added advantage, {} also provides final product assembly services, where they integrate the assembled PCB with other components, casings, and peripherals, providing a complete, ready-to-use product. This end-to-end manufacturing approach allows their clients to focus on product development and marketing, while {} takes care of the manufacturing process, ensuring a seamless experience.In conclusion, electronic PCBA factories like {}, with their expertise, advanced technology, and commitment to quality, are revolutionizing the electronics industry. Their comprehensive range of services, from PCB design to final product assembly, ensures an efficient and streamlined manufacturing process, meeting the growing demand for electronic devices worldwide. With continued innovation and adaptation to emerging technologies, {} is well-positioned to remain a leader in the industry and a preferred partner for businesses seeking electronic PCB assembly solutions.

Pricing Insights: Exploring the Latest Trends and Factors Impacting PCB Manufacturing Costs

Title: Growth in PCB Manufacturing Price Reflects Industry ExpansionIntroduction:The field of printed circuit board (PCB) manufacturing has witnessed significant growth in recent years, fueled by technological advancements and an increasing demand for electronic devices. Despite facing numerous challenges, the industry has managed to evolve and adapt to changing market trends, contributing to the development of various sectors worldwide. This article delves into the rising prices of PCB manufacturing and highlights the key factors behind this growth.Rising Demand and Technological Advancements:The global electronics market has witnessed a surge in demand for innovative and high-performance electronic devices, including smartphones, wearables, automotive components, and medical devices. With the rapid advancements in technology, these devices require highly sophisticated PCBs that offer improved efficiency, smaller footprints, and enhanced performance.Additionally, the emergence of emerging technologies such as 5G, Internet of Things (IoT), and artificial intelligence (AI) has further fueled the demand for advanced PCBs. These technologies demand complex and multi-layered PCB designs, pushing manufacturers to invest in sophisticated equipment, materials, and processes for production.Increased Material and Production Costs:The rising complexity and requirements of PCBs have led to increased material and production costs. PCB manufacturing involves various resources, including raw materials like copper, laminates, and solder masks, as well as specialized equipment, chemicals, and skilled labor. The prices of these inputs have experienced a steady increase, resulting in higher overall manufacturing costs.Furthermore, the demand for smaller, lightweight, and flexible PCBs has necessitated the use of advanced materials like flex and rigid-flex boards. These materials are more expensive compared to the traditional FR4 substrates, contributing to the rising PCB manufacturing prices.Environmental Regulations and Compliance:In recent years, there has been a growing emphasis on environmental sustainability and regulations concerning hazardous substances. Compliance with environmental standards, such as RoHS (Restriction of Hazardous Substances), has led to the adoption of more eco-friendly manufacturing processes and materials. These modifications come at an increased cost due to the additional efforts required to ensure compliance.Manufacturers have had to invest in new infrastructure, waste management systems, and training to adhere to these regulations. Such measures result in higher expenses during the production process, ultimately impacting the prices of PCB manufacturing.Supply Chain Challenges and Market Volatility:The PCB manufacturing industry heavily relies on a globalized supply chain. Disruptions in the supply chain, such as raw material shortages, geopolitical uncertainties, and transportation constraints, can have a significant impact on production and subsequently affect prices.The ongoing COVID-19 pandemic further highlighted the vulnerability of global supply chains. Factory closures, trade restrictions, and logistic challenges disrupted the supply of essential raw materials, leading to increased costs and delayed deliveries. The need for resilient supply chains to mitigate such risks has compelled manufacturers to invest in diversification and redundancy measures, contributing to the rise in PCB manufacturing prices.Conclusion:The rising prices of PCB manufacturing are a reflection of the industry's response to an increased demand for advanced electronic devices and technologies. Technological advancements, increased material and production costs, compliance with environmental regulations, and supply chain challenges all contribute to the overall increase in manufacturing expenses.Despite these challenges, the PCB manufacturing industry continues to evolve and adapt to market trends, fostering innovation and contributing to the growth of various sectors. Manufacturers are constantly seeking ways to optimize production processes, reduce costs, and improve efficiency, ensuring the delivery of high-quality and cost-effective PCBs to meet the growing demands of consumers worldwide.

Discover the Advantages of Fast PCB Assembly Services for Streamlined Production

XYZ Electronics Expands Its PCB Assembly Factory to Meet Growing Market Demand[City], [Date] - XYZ Electronics, a leading player in the electronics manufacturing industry, announced today that it is expanding its state-of-the-art PCB assembly factory to cater to the rising demand for its products. This move comes as a part of XYZ Electronics' strategic plan to consolidate its position as a reliable and efficient provider of cutting-edge electronic solutions.The decision to expand the factory was driven by the company's continuous efforts to meet the increasing market demand for high-quality PCB assembly services. With technological advancements, the demand for electronic devices is skyrocketing, and XYZ Electronics is well-prepared to serve this growing market segment.The expanded factory will enable XYZ Electronics to ramp up its production capacity significantly. The company has invested heavily in new equipment and machinery to ensure streamlined manufacturing processes and improve overall efficiency. With the addition of advanced automated assembly lines, XYZ Electronics now has the capability to assemble a wide range of circuit board designs with utmost precision and speed.Furthermore, the company's commitment to quality has also driven the expansion project. XYZ Electronics adheres to stringent quality control measures to ensure that every product leaving the factory is flawless. The newly expanded factory will allow the company to maintain its high standards and deliver flawless PCB assemblies to its customers consistently.The expansion project also emphasizes XYZ Electronics' dedication to sustainability and environmental responsibility. The company has implemented various eco-friendly measures in their manufacturing processes. These measures include recycling programs, energy-efficient machinery, and the use of environmentally friendly materials. By expanding its factory, XYZ Electronics aims to further reduce its carbon footprint and contribute to a greener future.In addition to meeting market demands, the expansion also creates employment opportunities for the local community. The new facility has created several job positions, ranging from skilled technicians to production line workers. XYZ Electronics believes in fostering a sense of community and providing employment opportunities for local talent.Mr. [Name], CEO of XYZ Electronics, expressed his enthusiasm about the expansion, stating, "This expansion highlights our commitment to continuously improving our services and meeting the evolving needs of our customers. With this larger facility, we will be able to serve a wider customer base and cater to their requirements promptly. We are confident that the expanded factory will solidify our position as a leading provider of PCB assembly services."The improved capabilities of the factory will undoubtedly benefit XYZ Electronics' existing customer base, which includes a wide range of industries such as aerospace, telecommunications, automotive, and medical devices. The company's extended capabilities will allow it to take on more significant projects, both in terms of volume and complexity, effectively catering to the diverse needs of its clients.As XYZ Electronics expands its PCB assembly factory, it demonstrates its commitment to staying at the forefront of the electronics manufacturing industry. With increased production capacity, advanced assembly techniques, and a focus on quality and sustainability, XYZ Electronics is well-positioned to meet the challenges and demands of the ever-evolving electronics market.

Top Supplier of PCB Board Assembly Services: Get Quality Assembly for Your Electronics

Title: Leading PCB Board Assembly Supplier Demonstrates Exceptional Quality and Technological ExpertiseIntroduction:In today's rapidly evolving technological landscape, the demand for high-quality electronic components such as printed circuit board (PCB) assemblies continues to grow exponentially. With a commitment to innovation, reliability, and excellent customer service, [PCB Board Assembly Supplier] has emerged as a trusted industry leader. As a premier supplier of PCB board assemblies, they have consistently demonstrated their prowess in providing cutting-edge solutions tailored to meet the needs of various sectors. This article will delve into [PCB Board Assembly Supplier]'s impressive capabilities, unparalleled product quality, and dedication to technological advancements.Exceptional Production Capabilities:[PCB Board Assembly Supplier] boasts state-of-the-art manufacturing facilities equipped with the latest automation technologies. These facilities are staffed by highly skilled technicians, engineers, and production personnel who facilitate seamless operations. The company's commitment to precision and reliability is evident throughout its production processes, from surface mount technology (SMT) to through-hole assembly and beyond. By adhering to stringent quality control measures, [PCB Board Assembly Supplier] ensures that each assembly meets or exceeds industry standards.Strategic Partnerships:Recognizing the importance of collaboration and innovation, [PCB Board Assembly Supplier] has forged strategic partnerships with leading electronic component distributors and manufacturers. These partnerships enable them to access top-of-the-line components at competitive prices, ensuring the highest quality PCB board assemblies for their customers. By harnessing the strengths of their partners, [PCB Board Assembly Supplier] can offer a wide selection of components, superior customization options, and expedited delivery times.Focus on Quality:Delivering products of outstanding quality is at the core of [PCB Board Assembly Supplier]'s business philosophy. The company adheres to rigorous quality control practices at every stage of the production process. From initial design and prototyping to final assembly and testing, each step is meticulously executed to produce reliable and high-performance PCB board assemblies.To further enhance quality control, [PCB Board Assembly Supplier] has implemented advanced inspection and testing techniques. These include automated optical inspection (AOI), X-ray inspection systems, in-circuit testing (ICT), functional testing, and environmental testing. By employing these cutting-edge methods, [PCB Board Assembly Supplier] eliminates potential defects, maximizes reliability, and ensures that only fully functional PCB board assemblies reach their customers.Technological Expertise:[PCB Board Assembly Supplier] prides itself on staying ahead of the technological curve. The company consistently invests in research and development, enabling them to offer innovative solutions to meet the diverse needs of their clients. By closely monitoring emerging industry trends and technological advancements, [PCB Board Assembly Supplier] continually expands its capabilities and expertise.Moreover, [PCB Board Assembly Supplier]'s team of highly skilled engineers and technicians possesses extensive knowledge and experience in areas such as high-speed PCB design, advanced soldering techniques, impedance control, and complex assembly requirements. This deep understanding of the intricacies of PCB assembly allows [PCB Board Assembly Supplier] to provide customized solutions for even the most demanding applications.Conclusion:With a steadfast commitment to superior quality, technological excellence, and customer satisfaction, [PCB Board Assembly Supplier] has firmly established itself as a leading provider of PCB board assemblies. Their unrivaled production capabilities, strategic partnerships, stringent quality control, and unwavering focus on innovation have garnered them a strong reputation within the industry. As the demand for reliable electronic components continues to grow, [PCB Board Assembly Supplier] remains poised to fulfill the needs of diverse sectors, driving the advancement of technology forward.

Top Pcb Pcba Manufacturers in China: Latest News Update

Title: Thriving Chinese PCB PCBA Manufacturers Continues to Lead Global MarketIntroduction:In recent years, China has emerged as a global powerhouse in electronics manufacturing, with its printed circuit board (PCB) and printed circuit board assembly (PCBA) manufacturers playing a pivotal role. With state-of-the-art infrastructure, advanced technology, and a skilled workforce, China's PCB PCBA manufacturers have become trusted partners for businesses worldwide. In this article, we will explore the success story of China's thriving PCB PCBA industry, highlighting the remarkable achievements of one of the industry's leading manufacturers.[Company Introduction]:[Necessity to remove brand name]: *The company we will be referring to in this article, although well-respected and successful, wishes to remain anonymous as per their company policy.With its headquarters located in the heart of China's booming electronics manufacturing sector, the anonymous PCB PCBA manufacturer has an impressive track record of delivering top-quality products to clients in various industries, including automotive, aerospace, telecommunications, and consumer electronics. Equipped with advanced machinery and cutting-edge technology, the company has established a comprehensive production line, ensuring high efficiency, reliable output, and strict adherence to international quality standards.News Content:1. Industry Overview:The global demand for PCB and PCBA continues to surge, and China has successfully positioned itself as a leading player in the industry. China's PCB PCBA manufacturers are renowned for their capability to deliver mass-produced, high-quality products with impressive precision, helping both domestic and international businesses bring their electronic innovations to life.2. Technological Advancements:China's PCB PCBA manufacturers have made significant strides in advancing their technology, thus retaining their competitive edge in the global market. The introduction of automated assembly lines, artificial intelligence (AI), and machine learning techniques have revolutionized the manufacturing process, providing faster turnaround time, enhanced efficiency, and improved product quality.3. Dependability and Reliability:The anonymous PCB PCBA manufacturer has built an enviable reputation for delivering dependable and reliable products to its global client base. Leveraging their vast experience, the company ensures thorough quality control measures are in place at every stage of production, ensuring that each PCB and PCBA meets the highest industry standards.4. Research and Development:Continuous investment in research and development has been a driving force behind the success of China's PCB PCBA manufacturers. Collaborative efforts with universities and research institutions have enabled them to stay at the forefront of technological advancements, enabling the production of complex and high-performance PCBs and PCBA solutions.5. Eco-friendly Manufacturing:Environmental sustainability is a key consideration for China's PCB PCBA manufacturers. The industry has been proactively adopting greener practices, such as using lead-free soldering techniques and reducing chemical waste. Companies are implementing environmentally friendly production processes, aligning with global environmental regulations and fostering a sustainable industry.6. Global Partnerships:China's PCB PCBA manufacturers have formed strategic alliances and partnerships with international businesses to expand their global reach. By building strong relationships, these manufacturers can offer comprehensive solutions to their clients, serving as a one-stop-shop for all their PCB and PCBA requirements.7. Impact on the Global Market:With its efficient manufacturing capabilities and cost-effective solutions, China's PCB PCBA industry has significantly influenced the global market dynamics. The country's manufacturers have been vital in the success of various industries dependent on PCB and PCBA assembly, bolstering innovation, supply chain efficiency, and cost optimization for businesses worldwide.Conclusion:China's PCB PCBA manufacturers, exemplified by the anonymous company discussed in this article, have successfully established themselves as key players in the global electronics manufacturing industry. Through their advanced technology, stringent quality control, continuous innovation, and strong client partnerships, these manufacturers continue to drive growth, efficiency, and reliability in an evolving marketplace. As the industry evolves further, China's PCB PCBA manufacturers are poised to continue leading the way in delivering superior products that power technological advancements globally.

Top Copper PCB Suppliers in China: Latest News and Insights

Title: China's Copper PCB Suppliers Revolutionizing Electronic Manufacturing ProcessesIntroduction: China has long been at the forefront of technological advancements, and the country's copper PCB (Printed Circuit Board) suppliers are playing a pivotal role in revolutionizing the electronic manufacturing sector. With their outstanding production capabilities, cutting-edge technologies, and commitment to quality, these suppliers are providing a range of innovative solutions for various industries. One of the leading copper PCB suppliers, [Supplier name], is a prime example of China's prowess in this field.[Supplier name] - An Overview:[Supplier name] is a renowned copper PCB supplier based in China, known for its high-quality products and exceptional services. With a rich history spanning over [number] years, the company has gained a strong foothold in the industry. [Supplier name] boasts an experienced team of professionals who continuously strive to develop and manufacture advanced copper PCBs to meet the demands of the ever-evolving electronics market.Advanced Production Capabilities:Equipped with state-of-the-art machinery and cutting-edge technologies, [Supplier name] offers a comprehensive range of copper PCB production capabilities. From single-sided to multi-layered boards, their production facilities accommodate various specifications and requirements. The company's advanced manufacturing processes ensure precision, reliability, and efficiency, enabling them to cater to the needs of diverse industries such as telecommunications, automotive, aerospace, medical, and consumer electronics.Commitment to Quality:[Supplier name] places immense emphasis on maintaining the highest standards of quality throughout the production process. Adhering to internationally recognized quality management systems like ISO [ISO certification], the company implements strict quality control measures at every step. From selecting premium raw materials to conducting rigorous inspections, [Supplier name] ensures that their copper PCBs comply with industry standards and customer specifications, leaving no room for compromise.Innovative Solutions for Various Industries:Recognizing the ever-increasing demand for reliable and high-performance electronic components, [Supplier name] continuously works towards developing innovative solutions. They collaborate closely with their clients to gain insights into their specific requirements and provide tailored copper PCB designs. By staying updated with the latest technological advancements, [Supplier name] excels in manufacturing flexible, rigid-flex, high-density interconnect (HDI), and aluminum-backed copper PCBs, among others. These solutions enable their customers to enhance the functionality and scalability of their electronic devices.Global Reach and Customer Satisfaction:[Supplier name] has established a strong global presence by supplying its copper PCBs to customers worldwide. With their commitment to customer satisfaction, the company has built long-term partnerships and earned a reputation for delivering high-quality products within the stipulated timeframes. [Supplier name]'s customer-centric approach manifests through their responsive technical support and efficient after-sales service, ensuring that their clients receive the necessary assistance throughout the production and implementation processes.Sustainability and Environmental Responsibility:In addition to technological advancements and stellar customer service, [Supplier name] is also keen on minimizing its environmental impact. The company actively adopts sustainable practices in its operations, including the adoption of eco-friendly materials, waste reduction strategies, and responsible disposal of hazardous substances. This commitment to environmental responsibility further enhances their reputation as a socially conscious and responsible copper PCB supplier.Outlook for China's Copper PCB Suppliers:As the electronics industry continues to expand and evolve, the future for China's copper PCB suppliers looks exceptionally promising. With their strong focus on research and development, investment in cutting-edge technologies, and commitment to quality, these suppliers are poised to play an increasingly significant role in shaping the electronics manufacturing landscape. Companies like [Supplier name] are leading the charge, ensuring that China remains at the forefront of technological innovation in the global market.Conclusion:China's copper PCB suppliers, exemplified by industry leaders such as [Supplier name], have transformed the electronic manufacturing sector through advanced production capabilities, commitment to quality, innovation, and global reach. With their continuous drive for excellence and sustainable practices, these suppliers are well-positioned to facilitate the development of groundbreaking electronic devices, further cementing China's status as a technological powerhouse.

Smd Circuit Manufacturer in China: A Rising Powerhouse in Electronics Industry

Title: Leading Circuit Manufacturer in China Amplifies Capacities to Meet Global DemandIntroduction:In recent years, the global electronic industry has witnessed remarkable growth, driven by advancements in technology, rising consumer demand, and the proliferation of digital devices. To cater to these evolving needs, China's renowned SMD Circuit Manufacturer, [brand name], has emerged as a reliable and innovative player in the market. With its commitment to producing high-quality circuit boards and components, the company has expanded its production capabilities to meet the increasing global demand. This article highlights the key attributes and accomplishments of China's leading circuit manufacturer and its ongoing efforts to enhance its operations.I. Company Background:Headquartered in [location], [brand name] has been a prominent player in the electronic manufacturing service (EMS) industry for over a decade. This privately-owned company has demonstrated consistent growth and resilience, becoming a trusted partner for numerous global electronic brands. Its commitment to technological advancement, research, and development, has earned it a solid reputation as a reliable circuit manufacturer. With a customer-centric approach and a commitment to quality, [brand name] continues to lead the market.II. Manufacturing Excellence:[Brand name] boasts state-of-the-art production facilities equipped with cutting-edge technology. Its manufacturing processes adhere to stringent international quality standards, ensuring the production of superior circuit boards and components. The company's commitment to excellence is reflected in its constant investment in research and development (R&D) activities, enabling it to incorporate the latest industry trends and advancements.III. Product Range:The comprehensive product range offered by [brand name] caters to diverse industry requirements. From single-sided to multi-layered PCBs, the company provides tailored solutions to meet the specific needs of its clientele. [Brand name] also specializes in surface mount technology (SMT) assembly, integrated circuit packaging, and PCB testing, delivering reliable and high-performance products at every stage of the manufacturing process.IV. Expanding Global Footprint:With a vision to meet the growing market demands, [brand name] has expanded its footprint globally. The company has established strong partnerships and collaborations in various regions, successfully positioning itself as a reliable supplier in international markets. By leveraging its extensive manufacturing capabilities and efficient logistics network, [brand name] is able to offer prompt and reliable deliveries worldwide.V. Embracing Industry Trends:Recognizing the significance of emerging industry trends, [brand name] actively pursues opportunities to diversify its offerings. With the increasing demand for flexible and wearable electronics, [brand name] is investing in the research and development of flexible PCBs and components. Moreover, the company is also exploring the incorporation of environmentally-friendly materials, contributing to sustainable manufacturing practices.VI. Commitment to Quality:[Brand name] places quality at the forefront of its operations. The company maintains strict quality control measures at every stage of production, ensuring that all products meet or exceed industry standards. By continuously investing in training and development programs for its workforce, [brand name] fosters a culture of excellence and accountability, resulting in the production of reliable and durable circuitry.VII. Future Prospects:The future looks promising for [brand name] as it continues to strengthen its position as a leading circuit manufacturer in China and beyond. With an unwavering commitment to innovation and customer satisfaction, the company remains dedicated to supporting the expanding technological landscape. [Brand name]'s relentless pursuit of excellence, coupled with its ability to adapt to industry trends, positions it as a key player in satisfying the evolving demands of the global electronic market.Conclusion:As the global electronic industry continues to experience rapid expansion, China's renowned circuit manufacturer, [brand name], emerges as a vital contributor to this growth. Through its dedication to quality, advanced manufacturing capabilities, and commitment to meeting the evolving demands of the market, [brand name] has established itself as a trusted partner to global electronic brands. Moving forward, the company remains focused on embracing innovation, diversifying its offerings, and reinforcing its position as a leader in the industry.

Top Turnkey PCB Suppliers: Streamline Your Production Efficiency

[News Title]Leading OEM Turnkey PCB Supplier Demonstrates Superior Manufacturing Capabilities[News Content]Company Introduction:In today's rapidly advancing technology-driven world, the role of Original Equipment Manufacturers (OEMs) has become increasingly vital. OEMs are responsible for designing, developing, and manufacturing electronic products and components for various industries. Among the prominent players in this domain is a renowned OEM turnkey PCB supplier that has firmly established itself as a leader when it comes to superior manufacturing capabilities.With years of experience, this esteemed company has successfully positioned itself as a one-stop solution provider, offering end-to-end PCB manufacturing services to satisfy the demands of a wide range of clients. By carefully combining the latest manufacturing technologies, state-of-the-art facilities, and a highly skilled workforce, the company has consistently delivered top-notch products, earning the trust and satisfaction of its valued customers.Superior Manufacturing Capabilities:The OEM turnkey PCB supplier prides itself on its exceptional manufacturing capabilities that set it apart from competitors in the industry. Let us delve into some of the key aspects that contribute to its success:1. Cutting-Edge Technology:Keeping up with the fast-paced advancement of technology is crucial in today's competitive landscape. This PCB supplier understands the significance of embracing new technologies and has consistently invested in state-of-the-art equipment. By utilizing advanced tools and software, they ensure precision, efficiency, and reliability in their manufacturing processes. This commitment to innovation enables them to deliver products of the highest quality that surpass industry standards.2. Comprehensive Turnkey Services:The company's comprehensive turnkey services cover all stages of PCB manufacturing, from design and prototyping to full-scale production. This holistic approach streamlines the manufacturing process, reduces lead times, and minimizes costs. By collaborating closely with clients, the OEM turnkey PCB supplier ensures that all their specific requirements and expectations are met, resulting in superior products that exceed customer satisfaction.3. Skilled Workforce:The success of any organization lies in the competence and dedication of its employees. Recognizing this, the OEM turnkey PCB supplier has assembled a highly skilled workforce that possesses in-depth knowledge and expertise in the field of PCB manufacturing. From engineers to technicians, every team member undergoes rigorous training programs to stay updated with the latest technological advancements. This commitment to continuous learning and improvement allows the company to consistently deliver top-quality products that meet the diverse needs of its customers.4. Stringent Quality Control:Quality is a non-negotiable aspect when it comes to PCB manufacturing. Understanding this, the PCB supplier implements stringent quality control measures at every step of the production process. From raw material inspection to final product testing, every stage is closely monitored to ensure adherence to international quality standards. This meticulous approach guarantees that every circuit board leaving their facilities is of the highest quality, free from any defects or inconsistencies.Conclusion:As the demand for OEM turnkey PCB manufacturing solutions continues to rise, it is crucial to partner with a trusted and reliable supplier. This renowned OEM turnkey PCB supplier, with its exceptional manufacturing capabilities, commitment to innovation, comprehensive services, skilled workforce, and stringent quality control, stands out as an industry leader. By consistently exceeding customer expectations, they have earned a notable reputation and are well-positioned to continue driving advancements in the field of PCB manufacturing.